Nov . 18, 2024 19:42 Back to list

Understanding the Functionality and Applications of Diaphragm Gate Valves in Industry

Understanding Diaphragm Gate Valves Key Features and Applications

Diaphragm gate valves are integral components in various industrial applications, renowned for their ability to manage the flow of fluids effectively while preventing contamination. These valves combine the principles of diaphragm valves and gate valves, making them suitable for a wide range of use cases, particularly in demanding environments.

What is a Diaphragm Gate Valve?

A diaphragm gate valve operates by lifting a diaphragm off the seat to allow fluid to pass through. This design prevents direct contact between the fluid and the valve components, which is crucial for maintaining the purity of the fluid, especially in industries such as pharmaceuticals, food and beverage, and biotechnology. The diaphragm serves as a flexible barrier that effectively seals the flow path when the valve is closed.

Key Features

One of the primary advantages of diaphragm gate valves is their excellent sealing capabilities. The diaphragm material, often made of elastomers or reinforced polymers, provides a tight seal that minimizes leakage, thereby enhancing operational safety and efficiency. Additionally, diaphragm gate valves are designed to handle corrosive and abrasive media, making them suitable for challenging conditions.

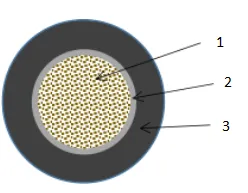

di gate valve

These valves also offer low maintenance requirements. Because the fluid does not directly contact the valve body, wear and tear is significantly reduced, extending the lifespan of the valve. Their straightforward design allows for easy installation and operation, which is an appealing aspect for many industrial operators.

Applications

The versatility of diaphragm gate valves makes them suitable for numerous applications. In the pharmaceutical industry, for example, they are used in processes that require high levels of hygiene and contamination prevention. Similarly, in the food and beverage sector, these valves are essential for maintaining product integrity and safety.

Moreover, diaphragm gate valves are found in water treatment plants, where they manage the flow of various liquids while preventing contamination from external sources. Their ability to function effectively under varying pressure conditions also makes them ideal for systems that involve fluctuating flow rates.

Conclusion

In conclusion, diaphragm gate valves stand out as a reliable solution for fluid control in various industries. Their unique design provides excellent sealing properties, enhances safety by preventing contamination, and reduces maintenance needs, which ultimately leads to increased operational efficiency. As industries continue to prioritize safety and quality, diaphragm gate valves will undoubtedly play a crucial role in facilitating these demands. Whether in pharmaceuticals, food processing, or water treatment, their application is integral to ensuring that processes run smoothly and safely. Understanding the importance of these valves enhances overall system design and functionality, making them indispensable in modern industrial settings.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025