Dec . 23, 2024 21:50 Back to list

Alternative Solutions for Diaphragm Air Valve Functionality and Efficiency

Understanding Di-AIR Valves An Overview

Di-AIR valves are an essential component in modern pneumatic systems, utilized primarily for controlling air flow in various applications. These valves play a crucial role in ensuring efficiency, safety, and optimal performance in numerous industrial and manufacturing processes.

What is a Di-AIR Valve?

A Di-AIR valve, often referred to as a diaphragm air valve, is designed to regulate the flow of compressed air or gases using a flexible diaphragm. This diaphragm acts as a barrier that opens or closes the valve in response to air pressure. The operation of the valve is relatively simple when air pressure is applied, the diaphragm moves to allow air to pass through, and when the pressure is removed, the diaphragm returns to its original position, closing the valve. This mechanism ensures a reliable and quick response to changes in pressure, making it highly suitable for various applications.

Key Features of Di-AIR Valves

1. Precision Control Di-AIR valves offer precise control over airflow, which is crucial in applications where accuracy is paramount. This capability helps in maintaining consistent pressure levels in pneumatic systems.

2. Durability Constructed from robust materials, these valves can withstand harsh operating conditions, including temperature fluctuations and exposure to corrosive substances. This makes them an ideal choice for industries such as food processing and pharmaceuticals, where hygiene and material integrity are critical.

3. Easy Maintenance The design of Di-AIR valves allows for straightforward maintenance and inspection. Many models can be disassembled quickly for cleaning or part replacement, which minimizes downtime and enhances productivity.

4. Versatility Di-AIR valves can be used in a wide range of applications, from simple air control systems to complex automated processes. They are often found in robotics, packaging machinery, and assembly lines, demonstrating their adaptability to different industrial needs.

Applications of Di-AIR Valves

Di-AIR valves are used across various industries, showcasing their versatility and reliability. Some common applications include

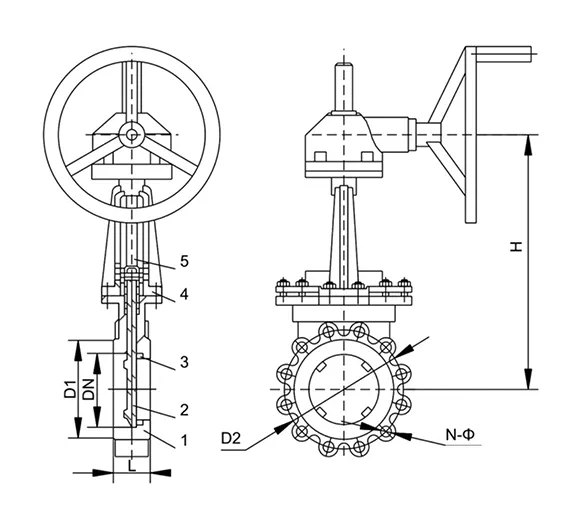

di air valve

1. Pneumatic Conveying Systems In industries that require the transport of bulk materials, Di-AIR valves help control the flow of air, ensuring materials move efficiently through the system without blockages.

2. Automated Machinery Many manufacturing processes rely on pneumatic actuators operated by Di-AIR valves to provide movement and control. For example, these valves can govern the airflow to robotic arms, enabling precise and coordinated movements.

3. Packaged Goods In the packaging industry, Di-AIR valves are utilized to control air pressure in food packaging machines, ensuring airtight seals and product longevity.

4. HVAC Systems Di-AIR valves play a role in heating, ventilation, and air conditioning systems by regulating the flow of air within ducts, contributing to energy efficiency and effective climate control.

Benefits of Using Di-AIR Valves

The integration of Di-AIR valves in pneumatic systems provides numerous benefits

- Efficiency By allowing for accurate control of airflow, these valves increase the efficiency of pneumatic systems, reducing energy consumption and operational costs.

- Safety The reliable operation of Di-AIR valves contributes to the safety of pneumatic systems by preventing over-pressurization and reducing the risk of system failures.

- Improved Performance The quick response time of Di-AIR valves enhances the performance of machinery and systems, leading to higher productivity levels.

Conclusion

In summary, Di-AIR valves are vital components in various industries, ensuring the efficient and safe operation of pneumatic systems. Their ability to provide precise control, durability, and easy maintenance makes them a preferred choice for manufacturers and engineers. As industries continue to evolve, the demand for reliable and efficient air control mechanisms like Di-AIR valves will likely grow, further solidifying their role in modern manufacturing and automation. Understanding their features and applications can help organizations leverage these essential components to improve their operational efficiency and maintain a competitive edge in the market.

Share