Dec . 12, 2024 11:20 Back to list

air compressor release valve

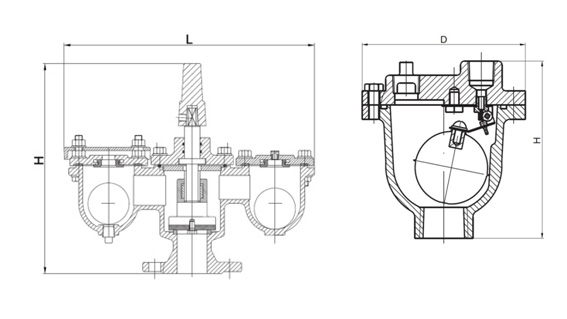

Understanding the Air Compressor Release Valve

Air compressors are essential tools in various industries, from construction to automotive repair. They provide the necessary power to operate pneumatic tools and equipment. One vital component of an air compressor is the release valve, often referred to as the safety valve or pressure relief valve. Understanding its function and importance can help ensure the efficient and safe operation of air compressors.

What is a Release Valve?

The release valve is designed to maintain safety within the air compressor system. It serves as a safety mechanism that prevents excessive pressure buildup, which could lead to catastrophic failures or damages. Typically, this valve is set to open at a specific pressure level, allowing excess air to escape when the compressor exceeds its safe operating limits.

Importance of the Release Valve

1. Safety Protection The primary role of the release valve is to safeguard the air compressor and its users. If the pressure in the compressor tank exceeds the designated limit, the release valve opens automatically, allowing air to escape. This function is crucial to preventing potential explosions or mechanical failures, ensuring the safety of both the equipment and the personnel operating it.

2. Maintaining Equipment Longevity Over time, excessive pressure can lead to wear and tear on the compressor's components. By ensuring that the pressure remains within safe limits, the release valve helps extend the life of the air compressor. Regularly functioning release valves minimize stress on the machinery, reducing the likelihood of costly repairs and replacements.

3. Enhancing Operational Efficiency A properly functioning release valve contributes to the overall efficiency of the air compressor. If the valve is stuck or malfunctioning, it can lead to improper pressure regulation, affecting the performance of the equipment. By maintaining optimal pressure levels, the release valve enables the compressor to operate smoothly and effectively, enhancing productivity.

air compressor release valve

How to Maintain the Release Valve

To ensure that the release valve remains effective, regular maintenance is essential

. Here are some tips for maintaining this crucial component1. Regular Inspections Routine checks of the release valve should be conducted to ensure it is functioning correctly. Look for signs of wear, corrosion, or any obstructions that could impede its operation.

2. Testing the Valve It is essential to periodically test the release valve to confirm that it opens at the appropriate pressure level. This can involve manually triggering the valve to see if it releases air as expected.

3. Consulting Professionals If you notice any issues with the release valve, it may be prudent to consult a professional technician. They can diagnose potential problems and make necessary repairs or replacements.

4. Keeping it Clean Regular cleaning of the release valve and its surrounding area can prevent dust and debris from affecting its performance. Ensure that the valve is free from any substances that may cause it to stick or malfunction.

Conclusion

The air compressor release valve is more than just a simple component; it is an essential safety feature that protects both the equipment and its operator. By understanding its function, importance, and maintenance needs, users can ensure the safe and efficient operation of their air compressors. Remember, regular inspections and timely maintenance can prevent numerous problems, leading to safer and more productive work environments.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025