Nov . 15, 2024 14:17 Back to list

12 knife gate valve

Understanding 12% Knife Gate Valves Applications and Advantages

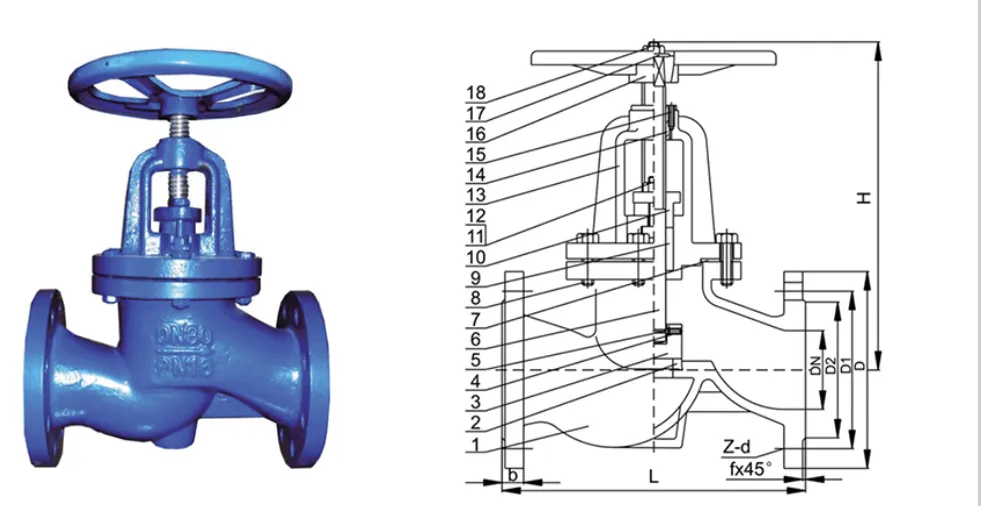

Knife gate valves are essential components in various industrial applications, particularly in handling slurries, thick liquids, and dry bulk materials. Among the different types of knife gate valves, the 12% knife gate valve has garnered attention for its specific design and functionality that cater to various operational needs.

What is a Knife Gate Valve?

A knife gate valve is a type of valve that uses a sharp-edged gate to cut through the medium, making it ideal for isolating flow in systems where liquids may contain large solids or where thick slurries are present. Unlike conventional gate valves, the knife gate valve is designed to handle challenging liquids with higher levels of solids. This design minimizes the risk of clogging and allows for a tight seal when closed.

The Significance of 12% Knife Gate Valves

The term 12% in the context of knife gate valves often refers to the specification related to the valve's design parameters, which aids in enhancing performance. Specifically, it could reference the gate’s angle, construction material, or the percentage of effective flow area in comparison to its overall size. This aspect is crucial because it determines how much fluid can pass through when the valve is in the open position.

Applications in Various Industries

12% knife gate valves are predominantly used in industries such as

- Water Treatment In wastewater management, these valves contribute to the effective control of sludge and other solids, allowing for smooth operation in treatment plants. - Mining and Minerals The mining sector relies on these valves to manage slurries and thick deposits, ensuring minimal downtime due to blockages. - Pulp and Paper Manufacturing Knife gate valves are vital in the pulp and paper industry, where they effectively handle the slurry of wood pulp and water. - Food and Beverage In food processing, maintaining hygiene is paramount. Stainless steel knife gate valves are used that meet the stringent safety standards while allowing the proper flow of viscous materials.

12 knife gate valve

Advantages of Using 12% Knife Gate Valves

1. Effective Isolation One of the main advantages of knife gate valves, including the 12% variant, is their ability to provide tight sealing, ensuring that no leakage occurs when the valve is closed. This isolation is critical in preventing spills and maintaining safety in operations.

2. Minimal Maintenance These valves are designed for durability with minimal moving parts. They typically require less frequent maintenance compared to other valve types, leading to lower operational costs over time.

3. Versatility The design allows them to handle a wide range of materials, making them suitable for various applications. Their functionality extends across different industries, demonstrating high versatility.

4. Ease of Operation Knife gate valves are easy to operate, either manually or through automated systems. This ease enhances operational efficiency and ensures that the system can quickly adjust to varying flow demands.

5. Cost-Effective Solution Due to their durability and low maintenance frequency, 12% knife gate valves present a cost-effective solution in the long run, reducing replacement and labor costs.

Conclusion

In conclusion, the 12% knife gate valve is a reliable choice for industries requiring efficient flow control of thick liquids, slurries, and solid-laden media. Its design and functionality meet the demands of challenging environments while ensuring durability, minimal maintenance, and operational effectiveness. As industries continue to evolve and face new challenges, the role of specialized valves like the 12% knife gate valve will become even more significant in promoting efficiency and safety.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025