Dec . 07, 2024 07:10 Back to list

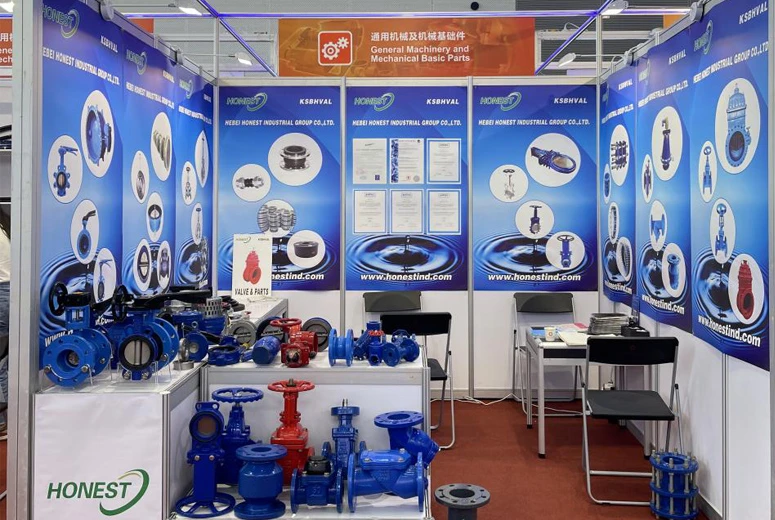

wafer butterfly valve manufacturers

Understanding Wafer Butterfly Valve Manufacturers A Comprehensive Overview

Wafer butterfly valves are vital components in various industrial applications, primarily designed to control the flow of fluids within a pipeline. Due to their efficiency, compact design, and cost-effectiveness, they have become increasingly popular in sectors like water treatment, oil and gas, chemical processing, and HVAC systems. The manufacturers of these valves play a crucial role in ensuring the availability and quality of these essential components. In this article, we will explore the key aspects of wafer butterfly valve manufacturers, including their manufacturing processes, market segments, and innovations.

What is a Wafer Butterfly Valve?

A wafer butterfly valve consists of a circular disc that rotates on a shaft to either permit or restrict the flow of fluid. The term wafer relates to the valve's compact design, which allows it to be sandwiched between two flanges in a pipeline. These valves are characterized by their low resistance to flow, making them efficient for regulating fluid movement. Typically, wafer butterfly valves are suitable for on/off control, throttling, and flow isolation in various applications.

Key Factors Behind the Growth of Wafer Butterfly Valve Manufacturers

1. Rising Demand Across Industries The demand for wafer butterfly valves has surged due to the rapid growth in industries, including water and wastewater management, oil and gas exploration, and power generation. As infrastructure projects expand and regulatory requirements for efficient fluid management intensify, manufacturers have ramped up their production capacities to meet market needs.

2. Technological Innovations Wafer butterfly valve manufacturers continuously invest in research and development to enhance product performance. Innovations include the use of advanced materials like stainless steel, plastic, and composite materials that offer superior resistance to corrosion and temperature fluctuations. Additionally, smart valve technology is being integrated into designs to enable remote monitoring and control.

3. Customization and Versatility Manufacturers are increasingly focusing on providing customized solutions to meet the specific requirements of various industries. This includes offering a range of sizes, pressure ratings, and end connections. Versatility in application is essential for manufacturers to cater to different sectors, leading to an increase in supplier options.

4. Sustainability Initiatives With a global shift towards sustainability, manufacturers are adopting eco-friendly practices in production. This includes minimizing waste, utilizing recyclable materials, and reducing carbon footprints in the manufacturing process. Such initiatives are attractive to socially responsible companies keen on environmentally sustainable practices.

Market Segmentation

wafer butterfly valve manufacturers

Wafer butterfly valve manufacturers operate in several market segments, including

- Water and Wastewater Treatment These valves are crucial for handling raw water intake, treatment processes, and wastewater management due to their ability to efficiently regulate flow and prevent backflow. - Oil and Gas In this sector, wafer butterfly valves are employed in pipeline systems for natural gas and crude oil transportation. Their ability to handle high-pressure environments makes them suitable for various applications in upstream, midstream, and downstream sectors. - Chemical Processing The chemical industry requires valves that can withstand corrosive materials and varying temperatures. Manufacturers provide specialized designs that ensure safety and reliability in chemical processes.

- HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, wafer butterfly valves control airflow and manage temperature, thereby contributing to energy efficiency.

Challenges Faced by Manufacturers

Despite the promising market environment, wafer butterfly valve manufacturers encounter several challenges

- Competitive Landscape The industry is highly competitive, with multiple players vying for market share. Manufacturers must differentiate themselves through quality, pricing, and innovation. - Regulatory Compliance Meeting stringent industry standards and regulations can often complicate the manufacturing process, necessitating investment in compliance training and technology.

- Supply Chain Disruptions Global supply chain issues can impact raw material availability, affecting production timelines and costs.

Conclusion

Wafer butterfly valve manufacturers play a pivotal role in various sectors where efficient fluid control is essential. By adapting to market demands through innovative technologies, customization, and sustainability practices, these manufacturers continue to thrive in a competitive landscape. As industries grow and evolve, the role of wafer butterfly valves will undoubtedly expand, solidifying the importance of these manufacturers in ensuring the reliability and efficiency of fluid management systems worldwide.

Share