Th12 . 11, 2024 09:57 Back to list

Durable Cast Iron Foot Valve for Efficient Water Control in Various Applications

The Importance and Functionality of Cast Iron Foot Valves

Cast iron foot valves are essential components in various fluid handling systems, especially in applications related to water management, irrigation, and industrial processes. These valves play a critical role in maintaining the efficiency and reliability of pumping systems by controlling the flow of liquids. In this article, we will explore the significance, construction, and operational features of cast iron foot valves.

What is a Foot Valve?

A foot valve is a type of check valve that is installed at the bottom of a suction line, typically submerged in water. Its primary function is to prevent the backflow of water when a pump is not operating. By maintaining a prime in the suction line, foot valves facilitate the smooth operation of pumps, ensuring that they do not lose their ability to draw water from the source.

The Role of Cast Iron in Foot Valves

Cast iron is a preferred material for manufacturing foot valves due to its durability and resistance to corrosion. The composition of cast iron, which includes carbon and silicon, imparts strength and weight to the valve, making it stable and robust. This is particularly important in harsh environments where the valve is subject to constant exposure to water, sediment, and other potentially corrosive elements.

Moreover, cast iron foot valves can withstand high pressures and temperatures, making them ideal for various industrial applications. Their longevity minimizes the need for frequent replacements, contributing to cost savings over time.

Construction of Cast Iron Foot Valves

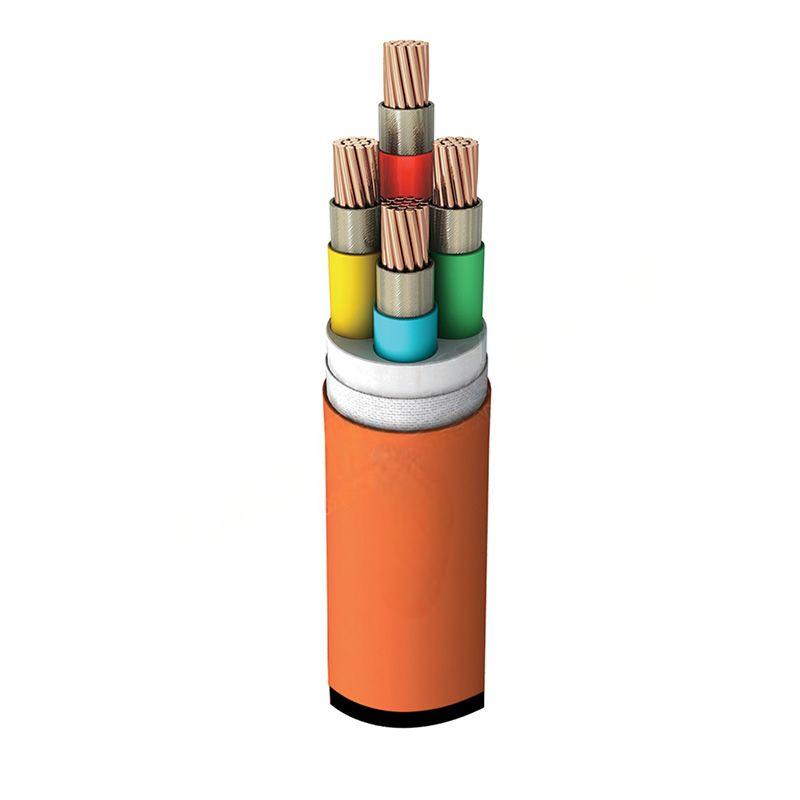

cast iron foot valve

A typical cast iron foot valve consists of several key components the valve body, strainer, and the internal check mechanism.

- Valve Body The body is made of cast iron and is designed to resist wear and corrosion while providing structural integrity. It usually features flanged or threaded connections for easy installation in suction lines. - Strainer Attached to the inlet of the valve, the strainer prevents debris and sediment from entering the valve and damaging the pump. This is crucial for maintaining the efficiency of the pumping system. - Check Mechanism The internal check mechanism, often a rubber or metal disc, allows the flow of water in one direction while sealing tightly when the flow reverses. This is essential for ensuring that water does not flow back into the source once the pump is turned off.

Operational Features

The operational efficiency of cast iron foot valves is paramount in various applications. When a pump is activated, water pressure opens the valve, allowing liquid to flow into the pump. Once the pump is shut off, the check mechanism swiftly closes, preventing backflow and maintaining the prime within the suction line. This cycle is vital for the consistent performance of pumps used in irrigation systems, municipal water supplies, and even in industrial processes.

Applications

Cast iron foot valves are widely used across many sectors. In agriculture, they are crucial for irrigation systems, where maintaining a steady water supply is essential for crop growth. In municipal water systems, foot valves help ensure consistent water pressure and supply to homes and industries. Similarly, in various industrial applications, they play a role in managing the flow of liquids, thus contributing to overall operational efficiency.

Conclusion

In conclusion, cast iron foot valves are integral components in fluid systems, providing stability, durability, and efficiency. Their robust construction and reliable operation make them ideal for various applications, from agriculture to industrial processes. Understanding their functionality and importance can assist in the selection and maintenance of these vital components, leading to optimized performance in fluid handling systems. As technology advances, the design and materials used in foot valves may evolve, but the fundamental role they play in preventing backflow will remain crucial in fluid management sectors.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025