نومبر . 09, 2024 18:06 Back to list

Flexible Rubber Check Valve for Reliable One-Way Flow Control in Various Applications

Understanding Rubber Check Valve A Comprehensive Overview

Rubber check valves are crucial components in various fluid handling systems, designed to prevent backflow and ensure the smooth operation of pumps and piping networks. These devices are essential in a range of industries, including water treatment, oil and gas, chemical processing, and wastewater management. In this article, we will explore the features, advantages, and applications of rubber check valves, enhancing your understanding of this vital technology.

What is a Rubber Check Valve?

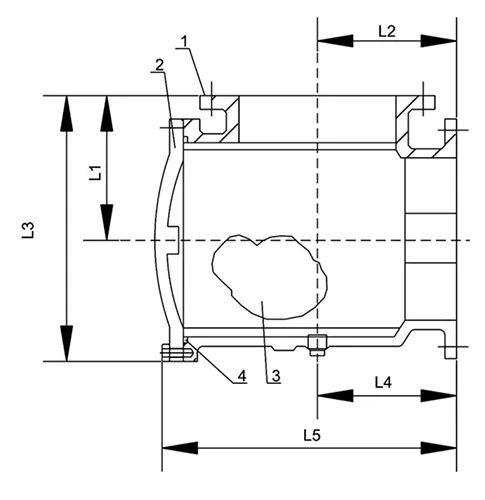

A rubber check valve is a one-way valve that allows fluid to flow in one direction while preventing backflow. It typically consists of a valve body made from durable materials, with a rubber diaphragm or flap that opens when fluid flows in the correct direction. When the flow reverses, the flap closes tightly, blocking the backflow effectively.

The primary material, rubber, is preferred for its flexibility and resilience, providing effective sealing and enabling the valve to operate under various pressure conditions. Additionally, rubber check valves can be manufactured in different hardness levels, allowing for customization based on specific operational requirements.

Key Features of Rubber Check Valves

1. Non-Return Functionality The primary function of a rubber check valve is to prevent the reverse flow of fluids, which could cause damage to pumps, equipment, or the entire system.

2. Simple Design Rubber check valves typically have a uncomplicated construction, which makes them easy to install and maintain. This design simplicity often results in lower operational costs.

3. Versatile applications Rubber check valves can be used in diverse environments, from residential plumbing systems to large industrial facilities, making them a versatile choice for many applications.

4. Wide Pressure Range These valves can handle a broad range of pressures, ensuring reliable performance in both low and high-pressure systems.

5. Corrosion Resistance Many rubber materials are resistant to corrosive fluids, making rubber check valves suitable for various chemical applications.

Advantages of Using Rubber Check Valves

rubber check valve

The use of rubber check valves comes with numerous advantages

- Cost-Effective Rubber check valves are generally more affordable than their metal counterparts, making them a cost-effective solution for many industries.

- Lightweight and Compact The construction of rubber check valves allows them to be lightweight and compact, making them easier to handle during installation.

- Noise Reduction The elastomeric materials used in rubber check valves can help absorb vibrations and reduce noise, particularly in fluid systems where sound dampening is crucial.

- Self-Cleaning Properties The flexible nature of the rubber can help prevent debris buildup, which is essential in maintaining consistent flow rates and prolonging the valve’s life.

Applications of Rubber Check Valves

Rubber check valves find applications across various sectors

- Water Treatment In municipal water systems, rubber check valves are commonly used to prevent backflow into treatment plants, ensuring clean water delivery.

- Pumps These valves are essential components in pump systems, where they protect pumps from damage caused by backflow.

- Irrigation Systems In agricultural settings, rubber check valves help prevent the siphoning of water back into irrigation lines, maintaining efficiency.

- Chemical Processing In chemical industries, these valves prevent the reverse flow of potentially hazardous fluids, ensuring safety and compliance.

In conclusion, rubber check valves are indispensable in a variety of fluid handling applications. Their straightforward design, cost-effectiveness, and reliable performance make them one of the preferred choices for engineers and technicians. As technology advances, the materials and designs of rubber check valves continue to evolve, catering to the ever-increasing demands of modern industries. Understanding their features, advantages, and applications can help businesses make informed decisions when selecting the appropriate valve for their needs.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025