دېكابىر . 11, 2024 20:13 Back to list

wire cable manufacturers

Understanding the Wire Cable Manufacturing Industry

The wire cable manufacturing industry plays a crucial role in various sectors such as telecommunications, construction, automotive, and electronics. As a vital component of modern infrastructure, wire cables facilitate the transmission of electricity and data, making them indispensable in today’s technological landscape. This article delves into the nuances of wire cable manufacturing, exploring the processes involved, the types of cables produced, and the leading manufacturers in the industry.

The Manufacturing Process

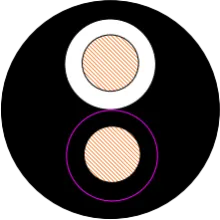

The production of wire cables typically begins with the drawing process, where raw materials, usually copper or aluminum, are drawn into thin wires. This involves pulling metal rods through a series of dies, which reduce their diameter while increasing their length. The quality of the wire is crucial, as it must meet specific electrical and mechanical standards.

Once the wires are drawn, they undergo annealing, which involves heating them to improve ductility and conductivity. After annealing, the wires are often coated with insulating materials such as PVC, polyethylene, or rubber to prevent electrical leakage and protect against environmental factors. The insulation process is vital for ensuring that the cables can withstand varying conditions, whether they are installed underground, underwater, or above ground.

Following insulation, cables may go through additional processes such as braiding, twisting, or bundling, depending on their intended use. For instance, multi-conductor cables may be twisted together to enhance flexibility and reduce electromagnetic interference. Finally, quality control measures are implemented to ensure that the finished products meet industry standards and specifications.

Types of Wire Cables

Wire cables can be categorized into several types, each designed for specific applications. The most common types include

1. Power Cables These are used for electricity transmission and distribution. They can be further divided into low, medium, and high-voltage cables, depending on their capacity.

2. Communication Cables Essential for telecommunication networks, these cables transmit data over long distances. Examples include fiber optic cables, coaxial cables, and twisted pair cables.

3. Control Cables Used in industrial applications, control cables help in the operation of machinery and equipment by transmitting signals rather than power.

4. Instrumentation Cables These are designed for the transmission of signals in process control systems, ensuring accurate measurements and control.

wire cable manufacturers

Leading Manufacturers in the Industry

The wire cable manufacturing landscape is home to numerous companies, some of which have established themselves as global leaders. Among them are

- Southwire Company, LLC Founded in 1933, Southwire is one of the largest wire and cable producers in North America. They offer a wide range of products, including copper and aluminum building wire, industrial cables, and specialty products.

- General Cable A leading manufacturer of copper, aluminum, and fiber optic wire and cable products. General Cable serves various sectors, including energy, industrial, and communications.

- Nexans This company operates worldwide, specializing in cable systems and services. Nexans focuses on sustainable solutions and innovation, catering to the energy and telecommunications industries.

- Prysmian Group As one of the world’s largest cable manufacturers, Prysmian Group produces a variety of cable products for energy and telecommunications. Their emphasis on research and innovation positions them at the forefront of the industry.

Future Trends

As technology evolves, so does the wire cable manufacturing industry. Key trends shaping the future include the increasing demand for renewable energy, which requires specialized cables for wind and solar applications. Furthermore, the rise of electric vehicles is leading to a greater need for high-performance power cables. Digitalization and the growth of smart cities are also driving advancements in communication cables.

Sustainability is becoming a focal point, with manufacturers striving to produce cables that minimize environmental impact. The use of eco-friendly materials and recycling processes is expected to gain traction as industries shift towards greener practices.

Conclusion

The wire cable manufacturing industry is a complex and dynamic sector that underpins many facets of modern life. As technology continues to advance, the demand for innovative, efficient, and sustainable cable solutions will drive growth and transformation in this essential industry. Understanding the manufacturing process, types of cables, and market leaders provides a comprehensive view of a field that is critical to both infrastructure and technological advancement.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025