دېكابىر . 04, 2024 18:21 Back to list

rubber lined butterfly valve

Exploring the Benefits and Applications of Rubber-Lined Butterfly Valves

Butterfly valves are essential components in various industrial applications, recognized for their simple design, durability, and ease of operation. Among the different types available, rubber-lined butterfly valves have gained significant popularity due to their unique advantages. This article delves into the features, benefits, and applications of rubber-lined butterfly valves, highlighting their importance in fluid control systems.

Understanding Rubber-Lined Butterfly Valves

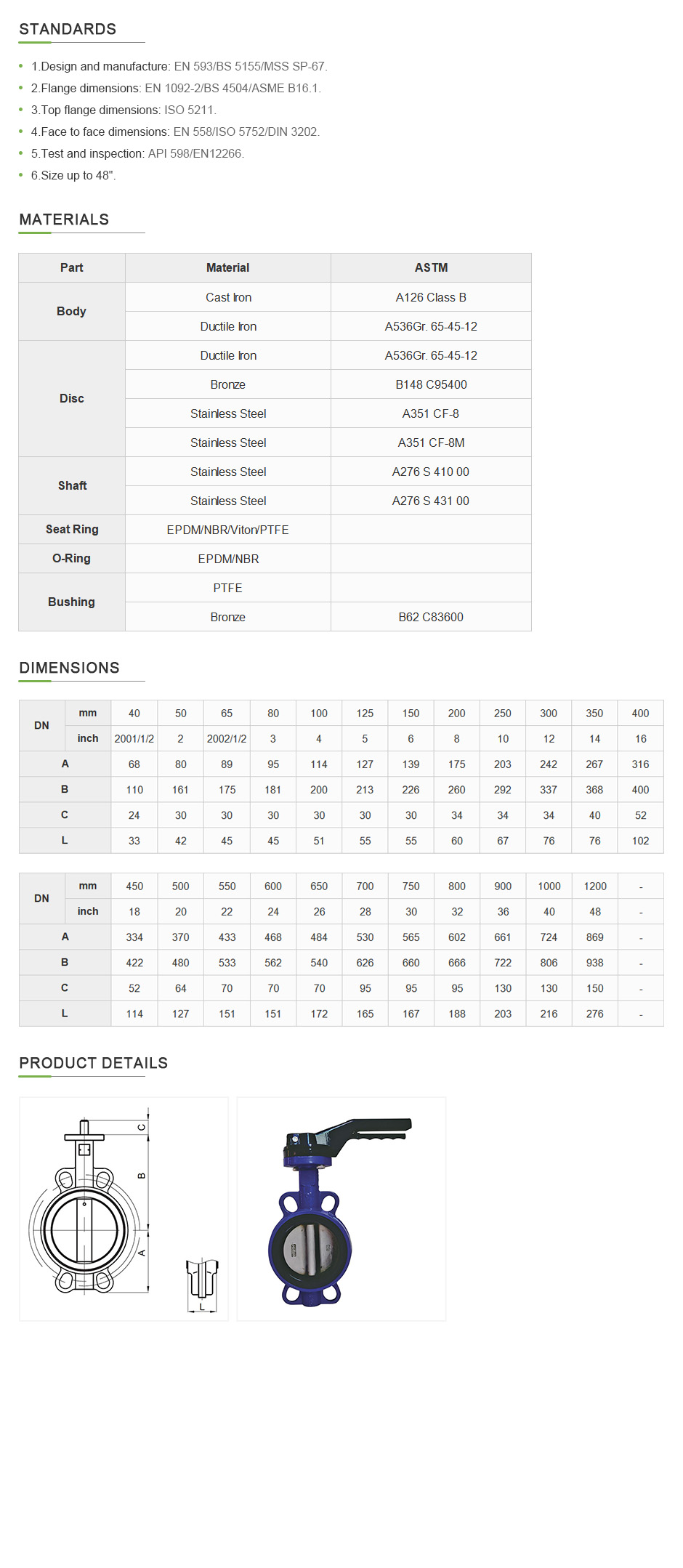

At its core, a butterfly valve consists of a disc that pivots around a central axis to open or close the flow of fluid. The addition of a rubber lining enhances the valve's functionality by providing effective sealing and corrosion resistance. The rubber liner, typically made from high-quality elastomers, covers the disc and the body of the valve, ensuring that it remains leak-free and resistant to various chemicals.

Key Features

1. Corrosion Resistance The rubber lining protects the metal components of the valve from corrosive fluids, significantly extending the valve's lifespan and reducing maintenance costs.

2. Versatile Sealing The flexibility of the rubber lining enables it to create a tight seal, preventing leaks and ensuring efficient flow control even under varying pressure conditions.

3. Lightweight Design Rubber-lined butterfly valves are generally lighter than their metal counterparts, making them easier to install and handle, especially in large-scale operations.

4. Easy Operation These valves can be operated manually, automatically, or remotely, providing flexibility in usage. The simple turning mechanism allows for quick adjustments to fluid flow.

Applications

rubber lined butterfly valve

Rubber-lined butterfly valves are widely used across various sectors due to their adaptability and reliability. Some common applications include

1. Water Treatment In municipal water systems, they regulate the flow of water and protect against contamination, ensuring clean drinking water for communities.

2. Chemical Processing These valves excel in handling corrosive and abrasive substances, making them ideal for chemical plants where a secure and reliable seal is paramount.

3. Food and Beverage Industry The non-toxic nature of the rubber lining allows for safe use in food processing applications, providing a sanitary solution for controlling flow.

4. HVAC Systems In heating, ventilation, and air conditioning systems, rubber-lined butterfly valves manage airflow and temperature control efficiently.

5. Pharmaceutical Industry The need for stringent hygiene and cleanliness standards makes rubber-lined butterfly valves a fantastic choice for pharmaceutical applications.

Maintenance Considerations

While rubber-lined butterfly valves are designed for longevity, regular maintenance is still crucial to ensure optimal performance. Some best practices include

- Routine Inspections Regularly check for signs of wear and tear, especially on the rubber lining, to identify potential issues early. - Proper Lubrication Ensure that the operating mechanisms are well-lubricated to facilitate smooth operation and prevent unnecessary strain on components. - Cleaning Depending on the application, it may be necessary to clean the valves periodically to remove any build-up that could hinder performance.

Conclusion

Rubber-lined butterfly valves are an integral part of many industrial processes, offering a myriad of benefits ranging from corrosion resistance to cost-effectiveness. Their versatility makes them suitable for diverse applications, from water treatment facilities to the food and beverage industry. By choosing rubber-lined butterfly valves, industries can ensure efficient fluid control while minimizing maintenance costs and extending equipment life. As technology continues to advance, these valves will undoubtedly play a crucial role in the evolving landscape of industrial automation and fluid management.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025