نويابىر . 12, 2024 04:19 Back to list

rising stem globe valve

Understanding Rising Stem Globe Valves Design, Function, and Applications

Rising stem globe valves are an essential component in various industrial applications, particularly in systems where precise flow control is critical. These valves serve not only as regulators of fluid flow but also as key elements in ensuring system safety and efficiency. In this article, we will explore the design, functionality, benefits, and applications of rising stem globe valves.

Design Characteristics

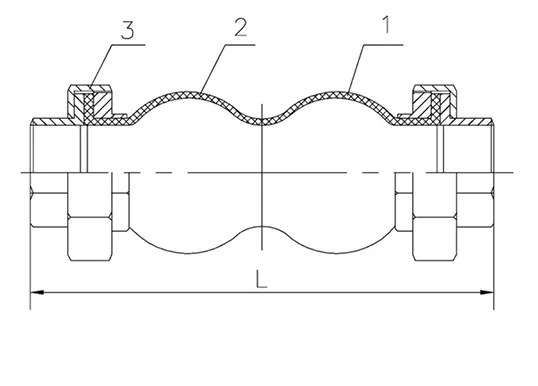

Rising stem globe valves are characterized by their unique design, which includes a moving stem that rises or lowers to open or close the valve. The main body of the valve is typically shaped like a globe, providing a streamlined interior that reduces turbulence and pressure drop. When the valve is activated, the disc moves up to allow fluid to pass through or down to block flow entirely.

The rising stem mechanism is a standout feature of these valves. As the operator turns the handwheel or actuator, the stem rises out of the valve body, giving a visual indication of the valve's position. This feature is not only practical but enhances safety, as operators can easily determine whether the valve is open or closed from a distance.

Functionality

The primary function of a rising stem globe valve is to manage the flow of fluids—liquids, gases, or slurries—within a system. The valve offers fine flow control, starting from a fully closed position and moving to various degrees of opening. This adjustability is particularly advantageous in applications requiring precise fluid management, such as in chemical processing, water treatment, and oil and gas pipelines.

Another aspect of their functionality is the ability to withstand high-pressure conditions. Rising stem globe valves are often constructed from robust materials, such as stainless steel or carbon steel, making them suitable for high-temperature and high-pressure environments. This durability ensures that they can maintain their effectiveness in demanding settings.

Benefits of Rising Stem Globe Valves

1. Precision Control One of the key advantages of rising stem globe valves is their ability to fine-tune fluid flow. Unlike other valve types that may only offer an entirely open or closed position, globe valves enable operators to modulate the flow to an exact level, facilitating precise operational requirements.

2. Back Pressure Management These valves excel in managing back pressure due to their design, which allows for a smooth and gradual flow transition. This feature helps in preventing surges and maintaining system stability.

rising stem globe valve

3. Durability and Longevity With appropriate material selection and maintenance, rising stem globe valves can provide a long service life. Their simple design makes them easy to repair and maintain, reducing downtime and associated costs.

4. Versatile Applications Rising stem globe valves can handle a variety of fluid types and are suitable for numerous industrial processes, including steam, gas, and liquid flow applications. Their versatility makes them a go-to choice across different sectors.

Applications Across Industries

Rising stem globe valves find extensive use in various industries

- Oil and Gas In petrochemical plants, these valves regulate the flow of crude oil and natural gas, crucial for safe and efficient operation.

- Chemical Processing Rising stem globe valves are used to control the flow of volatile chemicals, ensuring safe handling through precise control.

- Water Treatment In water treatment facilities, these valves help manage the flow of both raw water and treated water, playing a crucial role in maintaining water quality.

- Power Generation In power plants, they regulate steam and other fluids, ensuring that the systems operate within safe temperature and pressure thresholds.

Conclusion

Rising stem globe valves are indispensable tools in the realm of industrial fluid control. Their unique design allows for precision flow regulation, contributing significantly to operational safety and efficiency. With applications spanning oil and gas, chemical processing, water treatment, and power generation, these valves continue to be a vital component in various sectors. By understanding their functionalities and advantages, engineers and operators can make informed decisions on valve selection, ultimately enhancing the performance and safety of their systems.

Share