نويابىر . 24, 2024 22:30 Back to list

Metal Seat Gate Valve Features and Benefits for Industrial Applications

Understanding Metal Seat Gate Valves

Gate valves are an essential component in various industrial applications, providing efficient flow control in piping systems. Among the different types of gate valves, metal seat gate valves have gained prominence due to their durability and reliability, especially in severe environmental conditions. This article aims to delve into the characteristics, advantages, and applications of metal seat gate valves.

What are Metal Seat Gate Valves?

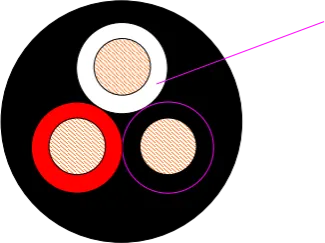

Metal seat gate valves are designed with a metal-to-metal sealing arrangement, which enhances their performance in high-pressure and high-temperature conditions. Unlike soft seat gate valves that use elastomeric materials, metal seat gate valves are typically made from robust metals such as stainless steel, carbon steel, or other alloys. This construction allows them to withstand significant wear and tear, making them suitable for demanding environments.

Key Features

1. Durability The primary advantage of metal seat gate valves is their durability. The metal seats can endure extreme operating conditions, including high temperatures and corrosive environments, without deforming or wearing out.

2. Pressure and Temperature Resistance These valves can operate effectively under high pressure and extreme temperatures, making them ideal for applications in industries such as oil and gas, power generation, and chemical processing.

3. Low Maintenance Due to their robust construction and resistance to wear, metal seat gate valves require less maintenance compared to their softer counterparts. This characteristic reduces downtime and operational costs.

4. Bidirectional Flow Metal seat gate valves allow for bidirectional flow, facilitating better control in various piping systems. This feature is particularly useful in applications requiring flow reversal.

5. Full Bore Design Most metal seat gate valves are designed with a full bore, meaning the internal diameter of the valve matches the diameter of the pipeline. This design minimizes pressure drop and improves flow efficiency.

metal seat gate valve

Advantages Over Other Types of Valves

While there are several valve types available, metal seat gate valves hold certain advantages over others such as globe valves or ball valves. Their ability to provide a straight-through flow with minimal resistance is essential in applications where fluid dynamics are critical. Moreover, them can be used in both on/off applications, as well as in throttling situations, depending on the design.

Applications

Metal seat gate valves are prevalent in numerous industries. Here are some key applications

- Oil and Gas These valves are used in upstream and downstream operations, including oil extraction, refining, and transportation. Their reliability in harsh conditions makes them a preferred choice.

- Power Plants In thermal power plants, metal seat gate valves control the flow of steam and water, ensuring efficient energy production. They also contribute to the safety of the plant by providing reliable shut-off capabilities.

- Chemical Processing The ability of metal seat gate valves to withstand corrosive substances makes them indispensable in chemical manufacturing. They are used in processes involving acids, solvents, and other aggressive chemicals.

- Water Treatment In water treatment facilities, metal seat gate valves are used to regulate water flow, helping maintain efficiency in purification processes.

Conclusion

Metal seat gate valves are a vital component in various industrial applications, standing out for their durability, pressure resistance, and low maintenance requirements. As industries continue to evolve and demand more robust solutions, these valves offer the reliability and performance needed to meet modern challenges. Their versatility across different applications ensures that they remain an essential choice for engineers and operators worldwide. Understanding their benefits can aid in selecting the appropriate valve for specific operational needs, ultimately enhancing system efficiency and reliability.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025