يانۋار . 09, 2025 10:39 Back to list

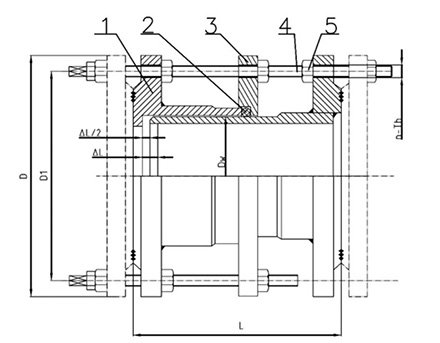

Wafer Type Butterfly Valve

Industrial valves play a critical role in controlling the flow and pressure within a wide range of mechanical systems, contributing to the efficiency, safety, and longevity of industrial operations. With over two decades of hands-on experience and deep industry knowledge, I can attest to the transformative impact of choosing the right valve for your specific application.

In an era where industrial efficiency and sustainability are more intertwined than ever, the role of eco-friendly valve technologies cannot be ignored. Advanced valve designs now incorporate features that reduce emissions and energy consumption, aligning with global efforts to minimize environmental impact. Industry professionals must stay abreast of these developments to make informed decisions that benefit both business performance and environmental considerations. Authentic user experiences further emphasize the importance of selecting high-quality industrial valves. Companies have reported significant cost savings and enhanced operational safety after upgrading to smart valve systems. These systems not only automate processes but also provide predictive maintenance alerts, reducing downtime and ensuring continuous, efficient operation. Ultimately, the credibility of industrial valve solutions is strengthened by robust after-sales support and regular maintenance services offered by reputable manufacturers. Long-term relationships with suppliers who provide comprehensive training, technical support, and maintenance contribute to maximizing valve lifespan and ensuring optimal performance. In conclusion, industrial valves are indispensable components in mechanical systems, with the right selection and implementation having profound effects on system efficiency and safety. Leveraging experience, expert knowledge, and trusted industry resources guarantees the best possible outcomes, validating the investment in high-quality valve solutions for industrial applications. Whether you are streamlining operations in oil and gas, water management, or chemical processing, prioritizing expertise and trustworthiness in industrial valve choices is essential for sustained success.

In an era where industrial efficiency and sustainability are more intertwined than ever, the role of eco-friendly valve technologies cannot be ignored. Advanced valve designs now incorporate features that reduce emissions and energy consumption, aligning with global efforts to minimize environmental impact. Industry professionals must stay abreast of these developments to make informed decisions that benefit both business performance and environmental considerations. Authentic user experiences further emphasize the importance of selecting high-quality industrial valves. Companies have reported significant cost savings and enhanced operational safety after upgrading to smart valve systems. These systems not only automate processes but also provide predictive maintenance alerts, reducing downtime and ensuring continuous, efficient operation. Ultimately, the credibility of industrial valve solutions is strengthened by robust after-sales support and regular maintenance services offered by reputable manufacturers. Long-term relationships with suppliers who provide comprehensive training, technical support, and maintenance contribute to maximizing valve lifespan and ensuring optimal performance. In conclusion, industrial valves are indispensable components in mechanical systems, with the right selection and implementation having profound effects on system efficiency and safety. Leveraging experience, expert knowledge, and trusted industry resources guarantees the best possible outcomes, validating the investment in high-quality valve solutions for industrial applications. Whether you are streamlining operations in oil and gas, water management, or chemical processing, prioritizing expertise and trustworthiness in industrial valve choices is essential for sustained success.

Share

Next: