يانۋار . 06, 2025 18:52 Back to list

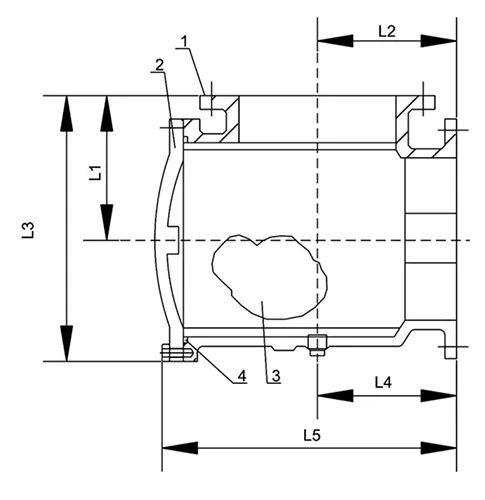

DIN Resilient Seat Gate Valve NRS

Gate valves, essential components for controlling the flow of liquid through pipelines, are highly regarded across multiple industries for their robust performance and adaptability. Understanding their design, functionality, and application can mark the difference between efficient operation and costly inefficiencies.

A gate valve, by its basic design, utilizes a sliding gate to open or block the flow path. This design is particularly effective in achieving a completely open or closed position, ensuring minimal pressure drop in the system. Specializing in various sectors, from oil and gas to pharmaceuticals, these valves are favored for their ability to manage diverse fluid types, including volatile chemicals and high-viscosity products.

Professionals in fluid control systems value gate valves for their durability and capability to handle high-pressure environments with precision. The design intricacy lies in the valve's internal components—such as the wedge, the stem, and the seat ring—which collectively contribute to its functionality. Expert handling and precise installation are crucial, guaranteeing reduced maintenance and extended service life, echoing the professionalism demanded by experienced operators.

Among their various applications, gate valves demonstrate exceptional efficiency in systems requiring full flow conditions or in operations where fluid needs to be isolated with high reliability. However, their primary role is not in throttling applications due to the potential for damage caused by the continuous exposure of the gate to partial fluid flow.

gate valve

Authoritative voices in the industry emphasize material choices when selecting a gate valve. Given the impact of temperature, pressure, and chemical composition of fluids, materials such as stainless steel, cast iron, or brass are chosen according to their compatibility and resistance attributes. This selection process underscores credibility in deploying gate valves within systems susceptible to corrosion or high wear.

While technology evolves, traditional gate valves maintain their position as trusted devices owing to their proven record and straightforward mechanical operation. The emphasis on rigorous testing and certification by recognized bodies provides additional trust, ensuring compliance with international standards – a reassurance for industries prioritizing safety and performance.

When integrating gate valves into industrial applications, consider trusted manufacturers with a background in innovation and customer satisfaction. Expertise in providing tailored solutions enhances operational success, reflecting a commitment to recognizing the specific needs while upholding industry standards.

In conclusion, the value of gate valves extends beyond their functional capabilities; they are pivotal in sustaining operational integrity and safety across industries. By understanding their nuances and leveraging expertise in their implementation, industries can ensure cost-effective and reliable fluid control, creating a trustworthy and authoritative foundation in fluid management systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025