فېۋرال . 15, 2025 06:44 Back to list

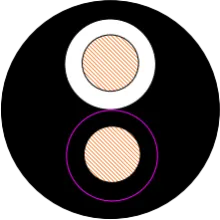

Single Plate Check Valve

Flow control check valves play an indispensable role in various industrial and residential applications, ensuring the safe and efficient passage of fluids while preventing backflow. As someone who's spent years in the field, I understand the critical importance of these components within complex systems.

Selecting the appropriate flow control check valve for specific applications demands a thorough understanding of system requirements and conditions. Factors such as operating pressure, temperature ranges, and fluid characteristics inform valve selection, ensuring optimal performance and longevity. Consulting with experts or reputable manufacturers can provide invaluable insights, offering tailored solutions that meet complex technical demands. Installation and maintenance best practices further ensure the reliability and performance of flow control check valves. Installation should adhere to manufacturer guidelines, verifying alignment, adequate support, and proper sealing to prevent leaks. Regular inspections and maintenance routines, such as clearing debris and checking for wear, bolster the valve's functionality and lifespan. As industries evolve and technological innovations emerge, the future of flow control check valves is promising. Developments in materials technology and smart monitoring systems are likely to enhance their operational capabilities, offering real-time data analytics and predictive maintenance solutions. This will not only improve efficiency but also elevate safety standards across diverse applications. Ultimately, flow control check valves are critical components within fluid systems, offering unparalleled protection against backflow while ensuring operational efficiency and reliability. Whether for industrial processes or residential plumbing, their expert design and dependable performance make them a cornerstone of modern engineering applications. By leveraging expert advice and embracing innovative technologies, businesses and consumers alike can maximize the benefits of these indispensable tools in their respective fluid systems.

Selecting the appropriate flow control check valve for specific applications demands a thorough understanding of system requirements and conditions. Factors such as operating pressure, temperature ranges, and fluid characteristics inform valve selection, ensuring optimal performance and longevity. Consulting with experts or reputable manufacturers can provide invaluable insights, offering tailored solutions that meet complex technical demands. Installation and maintenance best practices further ensure the reliability and performance of flow control check valves. Installation should adhere to manufacturer guidelines, verifying alignment, adequate support, and proper sealing to prevent leaks. Regular inspections and maintenance routines, such as clearing debris and checking for wear, bolster the valve's functionality and lifespan. As industries evolve and technological innovations emerge, the future of flow control check valves is promising. Developments in materials technology and smart monitoring systems are likely to enhance their operational capabilities, offering real-time data analytics and predictive maintenance solutions. This will not only improve efficiency but also elevate safety standards across diverse applications. Ultimately, flow control check valves are critical components within fluid systems, offering unparalleled protection against backflow while ensuring operational efficiency and reliability. Whether for industrial processes or residential plumbing, their expert design and dependable performance make them a cornerstone of modern engineering applications. By leveraging expert advice and embracing innovative technologies, businesses and consumers alike can maximize the benefits of these indispensable tools in their respective fluid systems.

Share

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025