سېنتەبىر . 22, 2024 12:31 Back to list

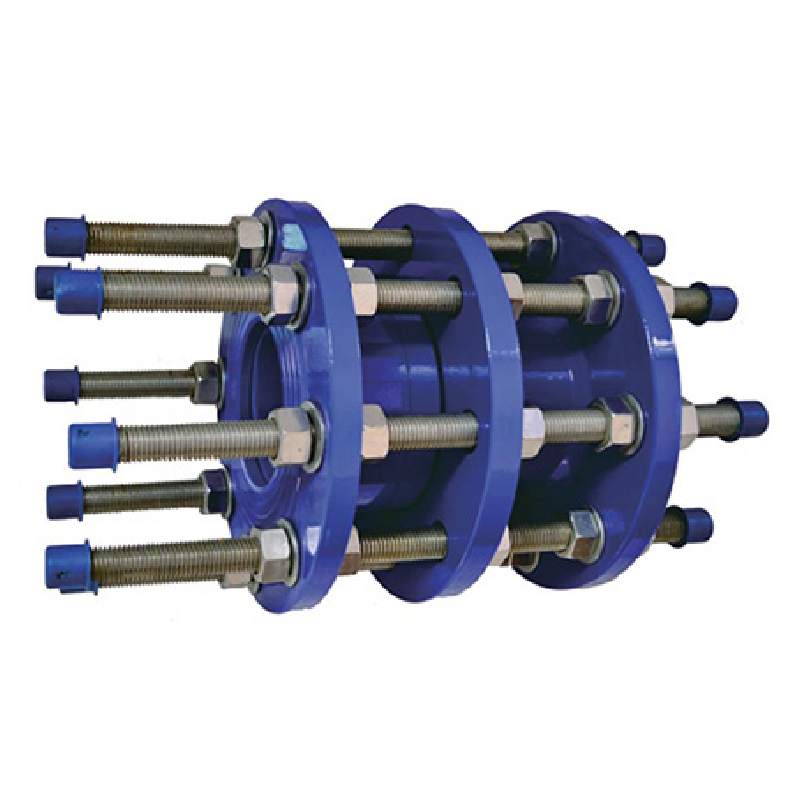

flexible rubber expansion joint

Flexible Rubber Expansion Joints Essential Components for Fluid Systems

In the world of fluid mechanics and piping systems, the importance of flexible rubber expansion joints cannot be overstated. These components play a critical role in accommodating movement, absorbing vibrations, and compensating for thermal expansion in various industrial applications. Flexible rubber expansion joints, designed from high-quality elastomers, provide the necessary flexibility to withstand the dynamic conditions encountered in modern piping systems.

Understanding the Functionality

The primary purpose of flexible rubber expansion joints is to facilitate the movement of piping systems with minimal stress on the joints and connectors. As temperatures fluctuate, pipes naturally expand and contract. Without the incorporation of expansion joints, this thermal movement can lead to significant stress and potential damage to the pipes and connected equipment. Expansion joints effectively absorb these movements, allowing the piping system to maintain its integrity while accommodating thermal changes.

Key Benefits

The benefits of using flexible rubber expansion joints extend beyond just accommodating thermal expansion. They also enhance the overall performance of the fluid system by

1. Vibration Absorption Machinery and fluid flow can generate vibrations that may impact the piping structure. Flexible rubber expansion joints minimize the transmission of these vibrations, protecting both the system and the connected structures.

flexible rubber expansion joint

2. Misalignment Compensation In engineered systems, slight misalignments in the piping can occur due to installation errors or lateral movements. Rubber expansion joints can compensate for these misalignments, maintaining a secure and leak-proof connection between pipes.

3. Corrosion Resistance Rubber materials are often selected for their resistance to various chemicals, making them ideal for use in environments where fluid properties can cause corrosion in metal piping. This capability extends the life of the entire system.

4. Ease of Installation Unlike rigid couplings or connections, flexible rubber joints are often easier and faster to install. This not only reduces labor costs but also minimizes system downtime during maintenance or installation phases.

Applications

Flexible rubber expansion joints are versatile components used across a range of industries. They are commonly found in water treatment facilities, chemical processing plants, HVAC systems, and even in the food and beverage sector. In each of these applications, the ability to accommodate movement while maintaining system integrity is vital for ensuring efficient and safe operations.

Conclusion

In summary, flexible rubber expansion joints are indispensable in ensuring the longevity and reliability of piping systems. By mitigating the effects of vibration, accommodating thermal expansion, and compensating for misalignments, these joints help maintain the structural and functional integrity of fluid systems. Their ease of installation and resistance to corrosive materials make them a preferred choice in various industrial applications. As industries continue to evolve and introduce more complex systems, the demand for effective and reliable components like flexible rubber expansion joints will only grow, underscoring their essential role in modern engineering solutions.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025