نويابىر . 20, 2024 06:57 Back to list

dual flap check valve

Understanding Dual Flap Check Valves Function, Design, and Applications

In the realm of fluid dynamics and control systems, valves play a crucial role in maintaining efficient operations across various industries. Among the myriad of valve types, the dual flap check valve stands out as a vital component for preventing backflow in piping systems. This article delves into the function, design, and applications of dual flap check valves, highlighting their importance in modern engineering.

Function of Dual Flap Check Valves

At its core, a dual flap check valve is engineered to allow fluid to flow in one direction while preventing reverse flow, thereby safeguarding downstream equipment from potential damage due to back pressure or backflow. This is especially critical in applications involving pumps or gravity-fed systems, where the risk of fluid flowing in the opposite direction can lead to significant operational and safety issues.

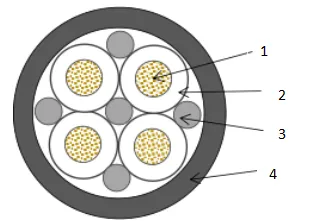

The dual flap design features two flaps that open simultaneously when fluid flows in the intended direction. As flow diminishes or attempts to reverse, the flaps close against their seats, creating a seal that effectively blocks backflow. The advantage of having two flaps over traditional single-flap designs includes improved performance in terms of responsiveness and reduced pressure drop across the valve, which is essential in high-flow applications.

Design Features of Dual Flap Check Valves

The construction of dual flap check valves is pivotal in their performance and longevity

. Typically, these valves are made from durable materials such as stainless steel, ductile iron, or plastic, depending on the specific application and the nature of the fluid being handled. The choice of material directly influences factors like corrosion resistance, weight, and temperature tolerance, making material selection critical for operational success.dual flap check valve

The dual flap mechanism is often designed to reduce turbulence, enabling smooth flow patterns that minimize energy loss. Furthermore, many modern dual flap check valves are equipped with cushioning devices or dampeners that further enhance performance by reducing the impact of sudden flow changes, thereby prolonging valve life and ensuring stable flow conditions.

Another essential design aspect is the valve's size and connection options. Dual flap check valves are available in various sizes, allowing for their integration into different pipeline systems. Standardized connections, such as flanged or threaded ends, facilitate ease of installation and maintenance, making them a popular choice across various sectors.

Applications of Dual Flap Check Valves

The versatility of dual flap check valves makes them suitable for a wide range of applications. They are commonly found in water and wastewater management systems, where they prevent backflow that could contaminate clean water supplies. In industrial settings, they are used in chemical processing, oil and gas, and power generation, where preventing reverse flow is critical for operational safety.

Additionally, dual flap check valves are employed in HVAC systems to prevent reverse airflow, ensuring that systems operate efficiently and maintaining desired temperatures. Their application extends to irrigation, firefighting systems, and even in the marine industry, where preventing backflow in bilge and engine cooling systems is of utmost importance.

Conclusion

In conclusion, dual flap check valves are indispensable components in various fluid handling systems, optimized for preventing backflow while ensuring minimal disruption to flow rates. Their dual flap design enhances performance, making them suitable for high-flow applications across multiple industries. As technology continues to advance, the design and functionality of these valves will likely evolve, incorporating more sophisticated features to meet the demands of modern engineering challenges. Understanding the significance and applications of dual flap check valves is essential for engineers and technical professionals alike, ensuring systems operate smoothly and efficiently.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025