دېكابىر . 12, 2024 09:22 Back to list

casting ball valve

Understanding Casting Ball Valves Functionality and Applications

Casting ball valves are pivotal components in various fluid handling systems, utilized primarily in industries such as oil and gas, water treatment, chemical processing, and HVAC. Their design represents a combination of functionality, reliability, and efficiency, making them an essential choice for regulating and controlling the flow of fluids.

What is a Casting Ball Valve?

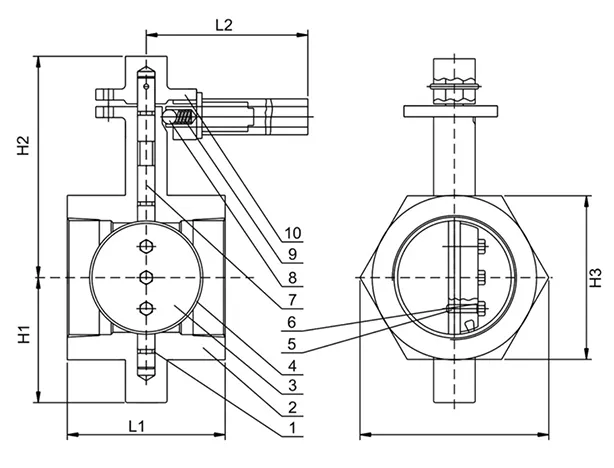

A casting ball valve is simply a type of ball valve where the body is manufactured through a casting process. Unlike forged valves, which are created by shaping solid metal, casting involves pouring molten metal into a mold, allowing for complex shapes and designs. The core feature of a ball valve is its spherical disc—a ball with a hole through it— that sits within the valve body and controls fluid flow. When the valve is turned, the ball rotates to either allow or block the passage of fluids.

Design and Construction

The construction of casting ball valves generally involves materials like stainless steel, carbon steel, or brass, depending on the application's requirements. The casting process allows for minimal material wastage and creates robust valves capable of withstanding high pressures and temperatures. Precision manufacturing ensures the internal surfaces of the valve are smooth, reducing friction and preventing wear, which in turn enhances the valve's lifespan.

Advantages of Casting Ball Valves

One of the primary advantages of casting ball valves is their ability to provide a reliable sealing mechanism. When the ball is turned to the closed position, it fits snugly against the valve seat, ensuring minimal leakage. This makes them ideal for applications where a tight seal is essential. Moreover, ball valves feature a 90-degree rotation, enabling quick and efficient operation—turning the valve from fully open to fully closed in seconds.

casting ball valve

Additionally, casting ball valves have a low-pressure drop, meaning they maintain efficiency when fluid is flowing through them. Their straightforward design also means that they require less maintenance than other types of valves, making them cost-effective over their lifespan.

Applications of Casting Ball Valves

The versatility of casting ball valves makes them suitable for diverse applications. In the oil and gas sector, they are indispensable for managing the flow of crude oil and natural gas. Their ability to operate under extreme pressures and temperatures allows them to function effectively in harsh environments.

In the water treatment industry, casting ball valves assist in the regulation of water flow in treatment plants and distribution systems. Their durability and tight seal ensure that treated water remains uncontaminated during distribution.

In chemical processing, these valves are essential for controlling the flow of corrosive and hazardous materials. The selection of appropriate materials for the valve body ensures resistance to the chemicals being handled, thereby enhancing safety and operational efficiency.

Conclusion

Casting ball valves represent a critical technology in modern fluid management systems. Their unique construction, combined with superior sealing capabilities and a straightforward operational mechanism, makes them a preferred choice across various industries. As innovations continue to emerge in the field of valve design and materials, the reliability and functionality of casting ball valves are likely to evolve even further, cementing their role in fluid control applications worldwide. Whether for commercial utilities or industrial processes, investing in high-quality casting ball valves can yield significant benefits in efficiency and safety.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025