نويابىر . 14, 2024 22:45 Back to list

8 inch check valve

Understanding the 8-Inch Check Valve An Essential Component in Fluid Systems

In the world of fluid management, ensuring the smooth and efficient flow of liquids and gases is paramount. One component that plays a vital role in this process is the check valve, specifically the 8-inch check valve. This article will delve into what an 8-inch check valve is, its functions, applications, and why it is critical in various industries.

What is an 8-Inch Check Valve?

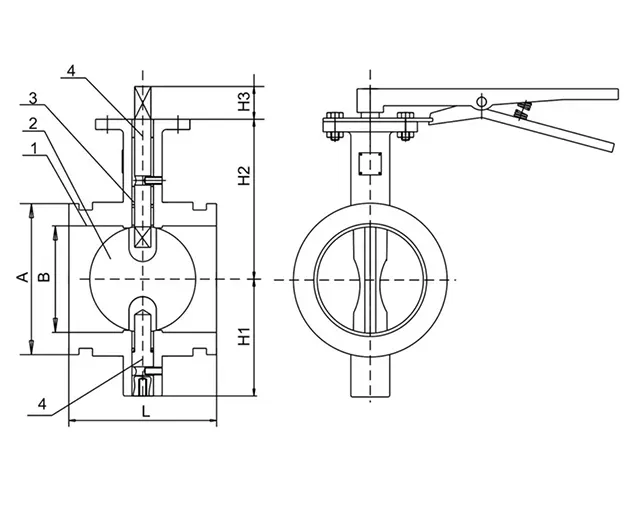

A check valve, also known as a non-return valve, is designed to allow fluid (liquid or gas) to flow in one direction only. The 8-inch measurement refers to its diameter, indicating the size of the pipe it is meant to be fitted into. Check valves come in various sizes, but the 8-inch variant is particularly common in industrial applications where larger volumes of fluid are handled.

The construction of an 8-inch check valve typically features a disc or a ball that moves within the valve body. This internal mechanism opens to permit flow in the forward direction and closes to prevent backflow, which can cause contamination, equipment damage, or system inefficiencies.

Functions of an 8-Inch Check Valve

The primary function of an 8-inch check valve is to prevent reverse flow. This is crucial in maintaining system integrity, especially in applications where backflow could lead to significant operational issues. For instance, in water treatment plants, an 8-inch check valve ensures that treated water does not flow back into the source, safeguarding the quality of the water supply.

8 inch check valve

Another essential function is to provide a means of isolating sections of a pipeline. In the event of maintenance or emergency situations, an 8-inch check valve can be used to segment the flow, enabling repairs without the need to shut down the entire system.

Applications in Various Industries

8-inch check valves are widely used in various sectors including water and wastewater treatment, oil and gas, chemical processing, and HVAC systems. In water treatment facilities, they are integral for maintaining directional flow and ensuring the consistency of treated water supply. In the oil and gas industry, these valves are vital for preventing backflow in pipelines, thereby protecting equipment and optimizing production efficiency.

The chemical processing industry also relies on 8-inch check valves to manage corrosive substances. The durability and resilience of materials used in these valves ensure long-term performance, even under harsh conditions. Furthermore, in HVAC systems, they help maintain airflow direction and pressure stability.

Conclusion

In conclusion, the 8-inch check valve is an indispensable component in various fluid systems. Its main function of preventing backflow not only protects equipment and ensures system efficiency, but it also plays a crucial role in maintaining safety and operational integrity across multiple industries. Understanding the significance of these check valves can lead to better decision-making when designing or maintaining fluid transport systems, ultimately resulting in improved reliability and efficiency in operations. Whether it’s in water treatment, oil production, or chemical processing, the 8-inch check valve consistently proves to be a vital asset in fluid management.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025