فېۋرال . 16, 2025 06:12 Back to list

2 inch rubber expansion joint

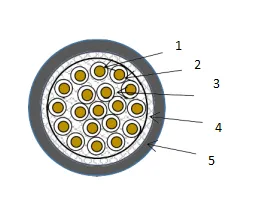

Rubber expansion joints have become an integral component in various industrial applications, providing flexible connections for pipes to accommodate movement, shock, vibration, and noise. Among the different types available, the 2-inch rubber expansion joint stands out for its versatility and efficiency. With years of engineering expertise and practical application experience, this article delves into the intricacies of these joints, highlighting their benefits and importance.

In today's environmentally-conscious world, the chemical compatibility of rubber expansion joints remains a significant concern. The materials used in constructing these joints are selected to be resistant to a variety of chemicals, oils, and even ozone, which makes them applicable in harsh and challenging environments. Understanding the specific requirements of an industrial application allows for proper selection, ensuring that the expansion joint can handle specific media without compromising its integrity. Trust in manufacturers that employ advanced quality manufacturing processes cannot be overstated. Reliable manufacturers conduct thorough testing and adhere to international standards such as ASTM and ISO, ensuring that the product can meet the rigorous demands of industrial applications. Collaboration with manufacturers who demonstrate expertise and adhere to these standards enhances trustworthiness, offering assurance that the expansion joints delivered are of the highest quality. Authoritative guidance from industry professionals on selecting the right type of 2-inch rubber expansion joint can be invaluable. Leveraging their expertise ensures that businesses choose the most appropriate type based on factors like pressure, temperature, and chemical exposure, which are quintessential for optimal performance. In conclusion, investing in a 2-inch rubber expansion joint is not merely about purchasing a component but rather procuring a solution that elevates system resilience and longevity. The understanding and technological advancements from professional manufacturers provide companies with the peace of mind that every expansion joint installed will address their specific operational challenges effectively. With the right maintenance and expert consultation, these joints will undoubtedly serve their purpose efficiently, improving not just the performance but also the sustainability of industrial systems over time.

In today's environmentally-conscious world, the chemical compatibility of rubber expansion joints remains a significant concern. The materials used in constructing these joints are selected to be resistant to a variety of chemicals, oils, and even ozone, which makes them applicable in harsh and challenging environments. Understanding the specific requirements of an industrial application allows for proper selection, ensuring that the expansion joint can handle specific media without compromising its integrity. Trust in manufacturers that employ advanced quality manufacturing processes cannot be overstated. Reliable manufacturers conduct thorough testing and adhere to international standards such as ASTM and ISO, ensuring that the product can meet the rigorous demands of industrial applications. Collaboration with manufacturers who demonstrate expertise and adhere to these standards enhances trustworthiness, offering assurance that the expansion joints delivered are of the highest quality. Authoritative guidance from industry professionals on selecting the right type of 2-inch rubber expansion joint can be invaluable. Leveraging their expertise ensures that businesses choose the most appropriate type based on factors like pressure, temperature, and chemical exposure, which are quintessential for optimal performance. In conclusion, investing in a 2-inch rubber expansion joint is not merely about purchasing a component but rather procuring a solution that elevates system resilience and longevity. The understanding and technological advancements from professional manufacturers provide companies with the peace of mind that every expansion joint installed will address their specific operational challenges effectively. With the right maintenance and expert consultation, these joints will undoubtedly serve their purpose efficiently, improving not just the performance but also the sustainability of industrial systems over time.

Share

Prev:

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025