سېنتەبىر . 22, 2024 07:22 Back to list

1600mm butterfly valve

Understanding the 1600mm Butterfly Valve A Comprehensive Overview

The butterfly valve is a crucial component in various industrial applications, particularly in managing the flow of liquids and gases. Among the various sizes available, the 1600mm butterfly valve stands out due to its significant diameter, enabling it to handle large volumes of fluids. This article delves into the characteristics, advantages, applications, and maintenance aspects of the 1600mm butterfly valve.

Characteristics of the 1600mm Butterfly Valve

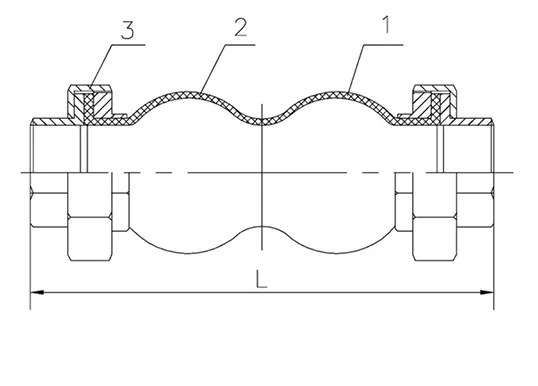

The 1600mm butterfly valve features a circular disc or butterfly that rotates to open or close the valve. This design allows for quick and efficient flow regulation. Typically constructed from high-quality materials such as stainless steel, carbon steel, or ductile iron, these valves exhibit durability and resistance to corrosion, making them suitable for various environments.

The valve operates using a simple mechanism where the disc is positioned in the center of the pipe. When the valve is closed, the disc creates a seal against the valve body, preventing flow. Conversely, when the valve is opened, the disc rotates, allowing fluid to pass through with minimal pressure drop. The 1600mm size makes it ideal for large pipes in systems that require high-volume throughput.

Advantages of the 1600mm Butterfly Valve

One of the primary advantages of the 1600mm butterfly valve is its lightweight and compact design. Compared to other types of valves, such as gate or globe valves, butterfly valves are easier to install and maintain due to their simpler construction. This can lead to reduced labor costs and installation time.

Another significant benefit is the high flow capacity. The 1600mm butterfly valve can accommodate substantial flow rates without significantly affecting the pressure drop across the valve. This characteristic is particularly important in applications where maintaining flow efficiency is critical.

1600mm butterfly valve

Additionally, the valve's cost-effectiveness makes it an attractive option for many industries. With lower material costs and reduced maintenance expenses, the overall lifecycle costs of using a butterfly valve can be lower compared to alternative valves.

Applications of the 1600mm Butterfly Valve

The 1600mm butterfly valve is widely used in various applications, including water supply and wastewater treatment, chemical processing, power generation, and HVAC systems. Its ability to handle different types of fluids, including slurries and gases under high pressure, makes it versatile.

In municipal water treatment facilities, these valves help regulate water flow and manage pressure, ensuring efficient operation. In industrial settings, they are essential for controlling the flow of steam, oil, and other fluids.

Maintenance and Considerations

Maintaining a 1600mm butterfly valve is relatively straightforward. Regular inspections are essential to ensure the disc operates smoothly and that seals are in good condition. Routine maintenance can prevent leaks and extend the lifespan of the valve.

In conclusion, the 1600mm butterfly valve is a vital component in modern industrial systems. Its lightweight design, high flow capacity, and cost-effectiveness make it an excellent choice for various applications, ensuring efficient and reliable operation in managing fluid flow. Proper maintenance and understanding of its characteristics can further enhance its functionality, making it a valuable asset in any application where it is utilized.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025