Дек . 05, 2024 03:44 Back to list

Durable and Versatile Flexible Rubber Joints for Various Applications

Understanding Flexible Rubber Joints Applications and Benefits

In the realm of engineering and plumbing, the function of joints and connectors is pivotal for maintaining the integrity and efficiency of systems. Among various types of joints available, flexible rubber joints stand out due to their versatility and adaptability. These joints are designed to accommodate movement, absorb vibrations, and facilitate the connection of pipes or machinery with ease.

What are Flexible Rubber Joints?

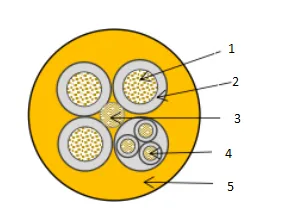

Flexible rubber joints, also known as rubber expansion joints or flexible connectors, are specialized devices made from high-quality rubber and reinforced with various materials, such as fabric or steel. They are designed to connect two or more sections of piping while allowing for some degree of movement. This flexibility is critical in applications where pipes might expand or contract due to temperature changes, or where they might experience vibrations from connected machinery.

Rubber joints come in various designs, including single sphere, double sphere, and tapered shapes, each catering to different applications and operational requirements. The material composition typically involves synthetic rubber, which is resistant to weathering, chemicals, and aging, ensuring long-lasting performance in various environments.

Key Benefits of Flexible Rubber Joints

1. Vibration Isolation One of the most significant advantages of using flexible rubber joints is their ability to dampen vibrations. In industrial settings where machinery operation produces substantial vibrations, these joints can help minimize wear and tear on connecting pipes and equipment.

2. Compensation for Misalignment Pipes are often subjected to slight misalignments due to installation variances or ground movement. Flexible rubber joints allow for slight angular or axial misalignments, reducing the risk of leaks or pipe breakage.

3. Temperature and Pressure Balance Fluctuations in temperature can lead to thermal expansion in pipelines, which may cause stress. Rubber joints are designed to handle such thermal movements, helping to maintain the structural integrity of the entire piping system.

flexible rubber joint

4. Ease of Installation Flexible rubber joints are relatively easy to install compared to rigid connectors. Their lightweight nature allows for simpler handling and quicker assembly, which is particularly beneficial in construction and maintenance scenarios.

5. Cost-Effectiveness While the initial cost of rubber joints might be higher than some alternatives, their durability and performance can lead to significant cost savings over time. By preventing leaks and minimizing maintenance needs, these joints contribute to more efficient operations.

Applications in Various Industries

Flexible rubber joints are utilized across diverse sectors, highlighting their critical role in modern engineering. In plumbing, they are commonly used to connect sections of sewer systems, irrigation pipelines, and water supply lines. Their ability to handle vibrations makes them ideal for use in industrial plants, breweries, and bottling facilities.

In the petrochemical industry, flexible rubber joints are employed in pipelines carrying crude oil and natural gas, as they can withstand harsh chemicals and extreme pressure fluctuations. Additionally, they are essential components in HVAC systems, where they help in connecting ducts while allowing for expansion and contraction due to temperature changes.

Maintenance and Care

To ensure the longevity and reliability of flexible rubber joints, regular inspection and maintenance are recommended. Checking for signs of wear, such as cracks or deformations, can help address potential issues before they escalate. Proper installation also plays a crucial role in maximizing the lifespan of these joints, as incorrect alignment can lead to premature failure.

Conclusion

Flexible rubber joints are invaluable components in countless applications, contributing to the smooth and reliable operation of various systems. Their benefits, including vibration absorption, temperature accommodation, and ease of installation, make them a preferred choice among engineers and industry professionals. As technology progresses, the design and materials used in these joints continue to evolve, promising even greater efficiency and longevity in the years to come. Understanding their significance not only enhances operational efficacy but also underscores the importance of quality components in industrial applications.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025