Ноя . 16, 2024 21:55 Back to list

flanged swing check valve

Flanged Swing Check Valve An Essential Component in Fluid Systems

The flanged swing check valve is a critical component in various fluid systems, particularly in the fields of water treatment, oil and gas, and chemical processing. This device is specifically designed to allow fluid to flow in one direction while preventing backflow. Its construction and working principles make it an excellent choice for many industrial applications, ensuring the efficiency and safety of fluid transportation.

Construction and Design

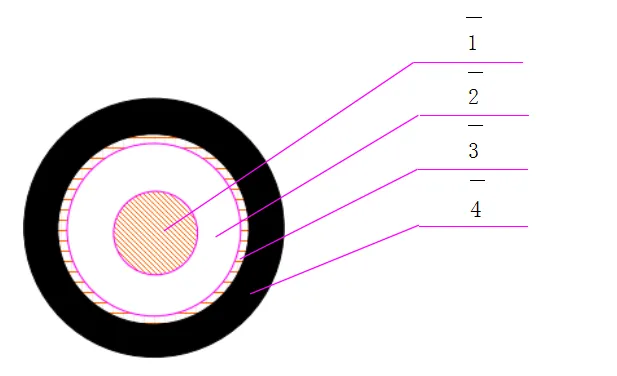

A flanged swing check valve typically consists of a valve body, a disc, and a hinge. The body is usually made from robust materials such as cast iron, bronze, or stainless steel, which are capable of withstanding high pressures and corrosive environments. The flanged design refers to the presence of a raised edge or lip around the valve body, allowing it to be bolted onto pipelines securely. This design ensures a tight seal and minimizes the risk of leaks.

The disc, which swings on a hinge, is the main feature that enables the one-way flow of fluid. When fluid enters the valve from the inlet side, it pushes the disc open, allowing flow. Conversely, when the fluid attempts to reverse direction, the disc swings back into a closed position, thereby blocking the flow and preventing backflow. This mechanism is crucial in protecting pipelines and equipment from damage caused by reverse fluid flow, also known as back siphonage.

Advantages of Flanged Swing Check Valves

1. Reliable Performance Flanged swing check valves are known for their reliability in preventing backflow. Their design allows for smooth operation with minimal turbulence, which is essential in maintaining fluid integrity.

2. Ease of Installation The flanged design allows for straightforward installation onto existing pipelines. Flanged fittings can accommodate different sizes and types of pipes, making them versatile for various system configurations.

flanged swing check valve

3. Low Pressure Drop Compared to other types of check valves, flanged swing check valves generally have a lower pressure drop. This means that they do not significantly impede the flow of fluid, contributing to overall system efficiency.

4. Durability and Longevity Constructed from robust materials, flanged swing check valves resist wear and corrosion, contributing to a longer lifespan. This durability is particularly important in environments where valves are exposed to harsh chemicals or extreme temperatures.

5. Minimal Maintenance These valves require minimal maintenance once installed, as their simple design and durable materials minimize the likelihood of mechanical failure.

Applications

Flanged swing check valves are widely used in various applications, including

- Water Treatment Plants They protect systems from backflow that could contaminate clean water supplies. - Oil and Gas Industry These valves prevent the reverse flow of hydrocarbons, which is vital for maintaining safety and operational efficiency. - Chemical Processing Flanged swing check valves ensure that hazardous chemicals flow correctly through processing systems without the risk of accidental backflow.

Conclusion

In conclusion, the flanged swing check valve plays a vital role in maintaining the reliability and efficiency of various fluid systems across multiple industries. Its robust construction, reliable performance, and ease of installation make it a preferred choice for engineers and system designers. By preventing backflow and ensuring the safe and efficient movement of fluids, flanged swing check valves are integral to modern industrial applications. As industries continue to evolve, these valves will remain an essential component in protecting systems and safeguarding fluid integrity.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025