Окт . 10, 2024 20:53 Back to list

Understanding Dismantling Joints for Effective Assembly and Disassembly Solutions

Dismantling Joints The Key to Structural Integrity and Efficiency

In the realm of engineering and construction, the integrity and longevity of structures heavily depend on the design and implementation of joints. Among various types of joints, dismantling joints have emerged as critical components that facilitate ease of maintenance, repairs, and upgrades in both architectural and mechanical assemblies. This article delves into the significance of dismantling joints, exploring their benefits, applications, and the future of this innovative technology.

Understanding Dismantling Joints

Dismantling joints, as the name suggests, are engineered connections that allow for the disassembly of components without causing damage. Unlike permanent joints, such as welded or glued options, dismantling joints are designed to enable straightforward assembly and disassembly. They are commonly used in scenarios requiring frequent maintenance or adjustments, making them especially valuable in industries such as construction, manufacturing, and HVAC (heating, ventilation, and air conditioning).

Importance of Dismantling Joints

1. Ease of Maintenance One of the most significant advantages of dismantling joints is their ability to simplify maintenance tasks. Structures with dismantling joints allow engineers and technicians to access internal components easily, which is crucial for inspections, repairs, and part replacements. This accessibility not only reduces downtime but also lowers maintenance costs.

2. Adaptability and Modularity Dismantling joints contribute to the adaptability of structures. For instance, in modular construction, components can be easily replaced or modified as designs evolve or as new technologies emerge. This flexibility is essential in responding to changing needs without the need for complete reconstruction.

3. Cost Efficiency Although the initial investment in dismantling joints may be higher compared to traditional permanent joints, the long-term savings are substantial. Reduced downtime for maintenance, along with the longevity of structures facilitated by easy repairs, results in lower overall lifecycle costs. In industrial applications, this can lead to improved productivity and reduced operational costs.

4. Environmental Considerations In an age where sustainability is paramount, the role of dismantling joints becomes even more critical. Structures designed with dismantling joints can be more easily deconstructed and recycled at the end of their life cycle. This reduced waste aligns with modern environmental standards and practices, promoting a circular economy in construction and manufacturing.

Applications of Dismantling Joints

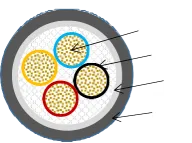

dismantling joint

Dismantling joints find applications across various sectors. In construction, they are integral to modular buildings that may need to be relocated or altered. In bridge construction, dismantling joints allow for easier repairs and maintenance of critical components without requiring complete structural shutdowns. In mechanical systems, such as piping and HVAC, dismantling joints facilitate quick access for maintenance while ensuring minimal disruption to the overall system.

Challenges in Implementing Dismantling Joints

Despite their advantages, the implementation of dismantling joints does come with challenges. The design process must account for factors such as load bearing, material compatibility, and environmental conditions. Engineers must ensure that dismantling joints maintain structural integrity while allowing for easy disassembly, which requires advanced engineering solutions and material science.

Moreover, the upfront costs associated with dismantling joints can be a barrier for some projects, particularly in budget-sensitive sectors. However, as awareness of the long-term benefits grows, more industries are beginning to incorporate them into their designs.

The Future of Dismantling Joints

As technology continues to evolve, the future of dismantling joints looks promising. Innovations in materials, such as lightweight composites and advanced metals, are paving the way for even more efficient and effective joint designs. Additionally, the rise of smart construction technologies, including digital twin modeling and augmented reality, will enable engineers to design, visualize, and test dismantling joints more thoroughly before implementation.

Furthermore, as industries increasingly prioritize sustainability, the demand for dismantling joints is expected to rise. Companies seeking to minimize their environmental impact will look to dismantling joints as a solution that aligns with their corporate social responsibility goals.

Conclusion

Dismantling joints represent a forward-thinking approach to design and construction, balancing the need for structural integrity with the demands of efficiency and sustainability. As the construction and manufacturing industries continue to evolve, so too will the role of dismantling joints. Their ability to facilitate maintenance, enhance adaptability, and contribute to environmentally friendly practices positions them as essential components of modern engineering. Embracing this technology will undoubtedly lead to smarter, more resilient structures capable of standing the test of time.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025