Dec . 11, 2024 04:00 Back to list

Lined Check Valve Applications and Benefits for Industrial Systems and Processes

Understanding Lined Check Valves A Comprehensive Overview

In the realm of fluid dynamics and control systems, check valves play a crucial role in maintaining the flow of materials while preventing backflow. Among the various types, lined check valves have gained prominence due to their unique design and material properties, making them suitable for specific applications, particularly in corrosive environments.

What is a Lined Check Valve?

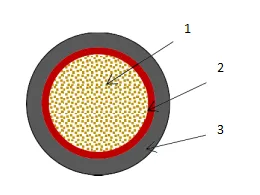

A lined check valve is a one-way valve that allows fluid to flow in only one direction. It features a lining made of materials such as fluoropolymer, rubber, or other plastics that protect the metal components from erosive or corrosive fluids. This lining acts as a barrier, preventing the aggressive nature of some fluids from degrading the valve's internal workings.

Key Features and Benefits

1. Corrosion Resistance The primary advantage of lined check valves is their exceptional resistance to corrosion. When dealing with harsh chemicals or corrosive substances, traditional metal valves may deteriorate quickly. Lined check valves, with their protective lining, ensure durability and longevity.

2. Reduced Maintenance Needs The enhanced durability of lined check valves translates to less frequent replacement and reduced maintenance costs. This is especially beneficial in industrial settings, where downtime can lead to significant losses.

3. Versatility Lined check valves are versatile and can be used in various applications, including chemical processing, oil and gas, water treatment, and power generation. Their ability to handle a wide range of fluids—from gases to viscous liquids—makes them an essential component in many systems.

lined check valve

4. Reliable Performance Lined check valves are designed to provide a reliable flow control mechanism, preventing backflow efficiently. The unique design minimizes turbulence, which is critical in applications that require precise fluid dynamics.

5. Non-Toxic and FDA Approved Materials Many lined check valves are manufactured from non-toxic materials, making them suitable for food and pharmaceutical applications. This adherence to regulatory standards ensures that the fluids being transported are not contaminated.

Applications of Lined Check Valves

Lined check valves are extensively used in industries where fluid integrity is paramount. For example, in the chemical industry, they are employed in the transportation of aggressive chemicals that can corrode standard metal valves. In wastewater treatment, lined check valves help manage the flow of potentially harmful substances while safeguarding the equipment from erosion and leaks.

Furthermore, in pharmaceutical manufacturing, where maintaining the purity of products is critical, lined check valves provide a reliable solution. The use of FDA-approved linings ensures that the fluid does not come into contact with harmful substances, maintaining compliance with health standards.

Conclusion

Lined check valves are vital components in various industries, providing reliable and controlled flow of liquids and gases. Their ability to resist corrosion and various environmental factors makes them a preferred choice for applications dealing with aggressive fluids. As industries continue to evolve and the demand for robust and reliable components increases, lined check valves will play an integral role in ensuring efficiency, safety, and performance in fluid management systems. Investing in high-quality lined check valves not only safeguards equipment but also contributes to the overall effectiveness of industrial operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025