Sep . 21, 2024 16:12 Back to list

lift check valve

Understanding Lift Check Valves

Lift check valves are an essential component in fluid systems, designed to prevent backflow and ensure the unidirectional flow of fluids. These valves are commonly used in various applications, ranging from industrial processes to residential plumbing. Understanding their functionality, benefits, and proper maintenance is crucial for engineers, technicians, and homeowners alike.

What is a Lift Check Valve?

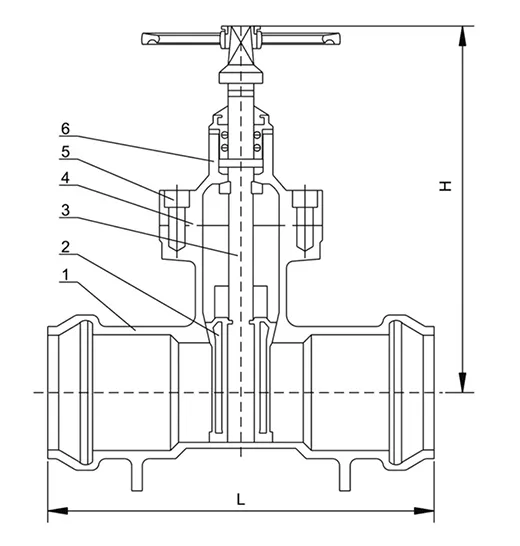

A lift check valve is a type of automatic valve that opens and closes based on the flow of media within a pipeline. The basic mechanism consists of a disc, which is lifted off its seat by the pressure of the fluid moving in the forward direction. When the flow reverses or stops, the disc falls back down, sealing against the seat and preventing backflow. This automatic operation eliminates the need for manual intervention, making lift check valves a popular choice in many fluid handling systems.

Key Features and Benefits

1. Preventing Backflow The primary purpose of a lift check valve is to prevent the backward movement of fluid in the system. This is essential in applications where contamination or damage can occur as a result of backflow.

2. Simple Design Lift check valves have a relatively simple design, which makes them easier to install and maintain compared to other types of check valves. Their straightforward mechanism allows for quick replacements and minimizes downtime in operations.

3. Versatility These valves can be used with various types of fluids, including water, oil, and gas. Their versatility makes them suitable for both industrial and residential applications, such as piping systems, fire protection systems, and HVAC installations.

lift check valve

4. High Flow Efficiency Lift check valves are designed to offer minimal resistance to flow when open. This characteristic ensures high flow efficiency in a system, reducing energy costs and improving overall performance.

Considerations for Use

While lift check valves offer numerous advantages, certain factors must be considered during selection and installation. The orientation of the valve, for instance, is crucial. Lift check valves are typically installed in a vertical position to ensure that the disc operates effectively. Moreover, proper sizing is important; an undersized valve could lead to turbulent flow, while an oversized valve might not close properly, leading to leakage.

Maintenance Practices

Regular maintenance is crucial to ensure the longevity and reliability of lift check valves. Here are some best practices

- Inspection Periodically check for any signs of wear, corrosion, or buildup of debris that could impair the valve's function. - Cleaning Clean the valve seat and disc to ensure a tight seal. This is especially important in applications involving viscous or sediment-laden fluids. - Testing Conduct regular operational tests to confirm that the valve opens and closes properly without any leaks.

Conclusion

In summary, lift check valves play a vital role in the efficient and safe operation of fluid systems. Their ability to prevent backflow, along with their simple design and high flow efficiency, makes them indispensable in various industrial and residential applications. By understanding their functionality and implementing proper maintenance practices, users can ensure optimal performance and longevity of these essential components.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025