Feb . 04, 2025 05:41 Back to list

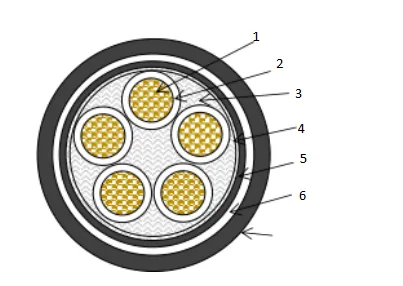

Low Smoke Fums,Fire Retardant,Halogen Fire Cable - Copper Conductors 0.6/1kV

Choosing the right industrial electric wire and cable can significantly impact the efficiency and safety of your business operations. In industrial contexts, the demand for reliable and high-performing electrical infrastructure is exceedingly high. Thus, understanding the nuances of cables, their applications, and the intricacies of installation are crucial.

The trustworthiness of a cable is further reinforced by sourcing from reputable manufacturers who offer warranties and support. Established brands with a legacy of catering to industrial needs often bring tested innovations to the market, incorporating the latest in material science and engineering principles. They typically offer consultations to ensure that the chosen products dovetail seamlessly with the existing technological framework, hence minimizing risks. Investing in quality cables also presents long-term benefits. Durable cables with efficient thermal management can prevent overheating, one of the most common causes of electrical fires. Furthermore, they reduce energy losses, helping industries to achieve sustainability goals and cut down on electricity costs. An often-overlooked aspect is the installation process. Installation by certified professionals ensures that connections are secure and that the integrity of the wire or cable is not compromised during setup. Correct installation practices prevent potential hazards such as short circuits and electric shocks, maintaining the safety of the workplace. In conclusion, the right industrial electric wire and cable are foundational to effective and safe industrial operations. Leveraging the experiences of seasoned experts, understanding technical specifications, adhering to standards, and choosing trusted manufacturers are all strategies that lead to a wise investment in these critical components. The advantages extend beyond operational efficiency, contributing to the overall sustainability and safety of industrial environments.

The trustworthiness of a cable is further reinforced by sourcing from reputable manufacturers who offer warranties and support. Established brands with a legacy of catering to industrial needs often bring tested innovations to the market, incorporating the latest in material science and engineering principles. They typically offer consultations to ensure that the chosen products dovetail seamlessly with the existing technological framework, hence minimizing risks. Investing in quality cables also presents long-term benefits. Durable cables with efficient thermal management can prevent overheating, one of the most common causes of electrical fires. Furthermore, they reduce energy losses, helping industries to achieve sustainability goals and cut down on electricity costs. An often-overlooked aspect is the installation process. Installation by certified professionals ensures that connections are secure and that the integrity of the wire or cable is not compromised during setup. Correct installation practices prevent potential hazards such as short circuits and electric shocks, maintaining the safety of the workplace. In conclusion, the right industrial electric wire and cable are foundational to effective and safe industrial operations. Leveraging the experiences of seasoned experts, understanding technical specifications, adhering to standards, and choosing trusted manufacturers are all strategies that lead to a wise investment in these critical components. The advantages extend beyond operational efficiency, contributing to the overall sustainability and safety of industrial environments.

Share

Prev: