Dec . 04, 2024 17:49 Back to list

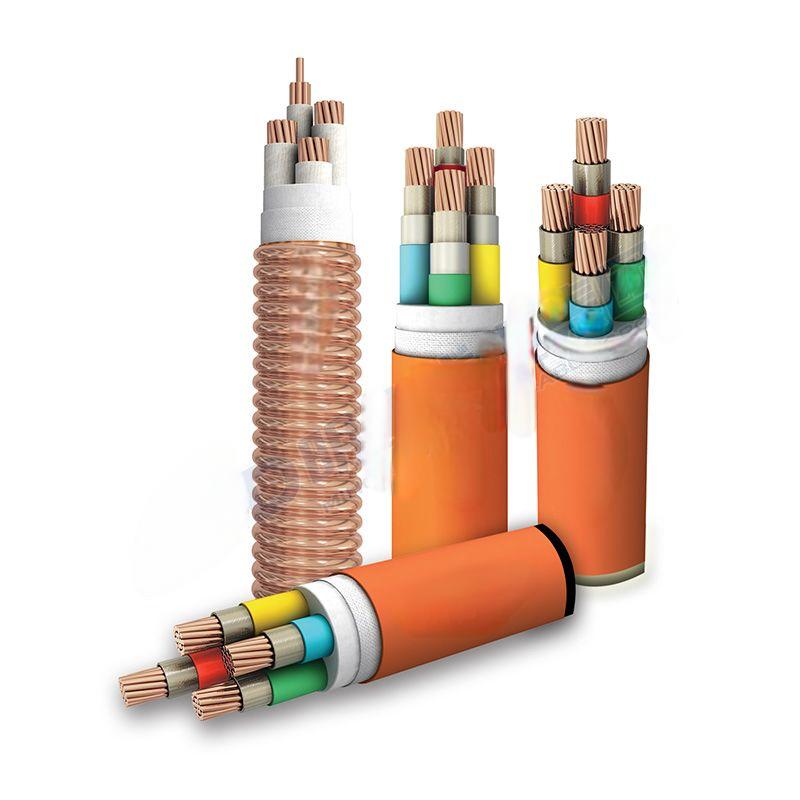

coated wire cable

Understanding Coated Wire Cable Applications, Advantages, and Innovations

Coated wire cables are an essential component in the modern electrical and communication industries. They are commonly used across various applications, ranging from automotive systems to industrial machinery, and even in consumer electronics. The term coated wire cable refers to wire that is coated with a protective insulating material, which not only enhances the wire's durability but also improves its performance in various environments. Understanding the significance of coated wire cables and their multifaceted applications is crucial for anyone interested in electrical engineering and technology.

Composition and Types of Coated Wire Cable

At its core, a coated wire cable consists of conductive materials, typically copper or aluminum, which are enveloped in one or more layers of insulating materials. These materials can vary widely, including polyvinyl chloride (PVC), polyethylene, rubber, or fluoropolymer, each selected based on the specific needs of the application. For instance, fluoropolymer coatings provide excellent thermal resistance and are ideal for high-temperature applications, while PVC is often used in household and light industrial settings due to its flexibility and cost-effectiveness.

Coated wire cables can be classified into several types based on their intended use. These include controlled extension cables, which are designed for automated control systems; power cables for electrical distribution; and shielded cables that offer protection against electromagnetic interference (EMI). This diversity makes coated wire cables suitable for a broad spectrum of industries, including telecommunications, automotive, aerospace, and construction.

Advantages of Using Coated Wire Cables

One of the primary advantages of coated wire cables is their enhanced protection against environmental factors. The coating serves as a barrier against moisture, heat, and chemicals, thereby preventing corrosion and increasing the longevity of the wire. This is particularly important in industries where reliability and safety are paramount, such as in aerospace and medical applications. Furthermore, coated cables can withstand extreme conditions ranging from sub-zero temperatures to scorching heat, making them ideal for use in diverse climates and environments.

Another significant advantage is the improved electrical performance of coated wire cables

. The insulation reduces losses due to leakage currents and minimizes the risk of short circuits, which can lead to equipment failures and safety hazards. Additionally, specific coatings can provide enhanced dielectric strength, ensuring that cables can handle high voltages without breaking down.Applications Across Industries

coated wire cable

Coated wire cables find usage in a myriad of applications across various industries. In the automotive sector, they are critical for wiring harnesses, where they connect various electronic components, ensuring the smooth operation of modern vehicles loaded with advanced technology. The ability to withstand vibration, heat, and humidity makes them invaluable for automotive safety and functionality.

In the telecommunications industry, coated wire cables are essential for data transmission. They are used in both communication devices and their infrastructure, such as in fiber-optic cables, where the coating protects delicate fibers from damage and environmental factors. The demand for high-speed internet and mobile connectivity continues to drive innovations in coated cable technology.

Moreover, in industrial manufacturing, these cables are pivotal in automation and robotics. They support control systems, sensors, and machinery, playing a critical role in enhancing productivity and operational efficiency.

Recent Innovations

Recent trends have seen advancements in the composition and manufacturing processes of coated wire cables. Innovations in materials technology have led to the development of lightweight, ultra-flexible cables that can be easily integrated into compact electronic devices. Additionally, advancements in sustainable materials have prompted manufacturers to explore eco-friendly coatings that reduce environmental impact without compromising performance.

Moreover, as industries move towards smart technologies and the Internet of Things (IoT), the demand for high-performance coated wire cables continues to rise. Manufacturers are increasingly focusing on creating cables with enhanced data transmission capabilities, durability, and thermal management properties to meet the evolving needs of modern technology.

Conclusion

Coated wire cables play a crucial role in the operation and efficiency of various systems and technologies across industries. Their protective coatings offer significant advantages in terms of durability, electrical performance, and safety. As advancements in materials science continue to evolve, coated wire cables will undoubtedly remain at the forefront of technological innovation, paving the way for a more connected and efficient future. Understanding their applications and benefits can help industries leverage this essential element to enhance performance and productivity in their operations.

Share