Dec . 11, 2024 02:00 Back to list

Understanding the Functionality and Advantages of Water Ball Valves for Efficient Flow Control

Understanding Water Ball Valves A Comprehensive Overview

Water ball valves are crucial components in various plumbing and industrial applications, characterized by their simple design and reliable performance in controlling water flow. These valves get their name from the spherical ball that resides inside them, which can rotate to either allow or block the passage of water. In this article, we will explore the operational principles, advantages, applications, and maintenance of water ball valves.

Operational Principles

The fundamental design of a water ball valve consists of a hollow, perforated sphere (the ball) that is connected to a lever or handle. When the handle is turned to a 90-degree angle, the ball rotates, aligning its hole with the flow path, which allows water to pass through. Conversely, when the handle is turned to the perpendicular position, the solid side of the ball blocks the flow, effectively closing the valve. This straightforward mechanism is what makes ball valves so user-friendly and dependable.

One significant advantage of a ball valve is its ability to create a tight seal. When closed, the ball presses against the valve seat, ensuring minimal leakage. This characteristic makes ball valves ideal for applications requiring a reliable shut-off, especially in high-pressure systems.

Advantages of Water Ball Valves

1. Durability Water ball valves are constructed from robust materials such as brass, stainless steel, or PVC, allowing them to withstand harsh operating conditions, including high pressure and temperature.

2. Versatility These valves are suitable for various fluids, including water, oil, and gas, making them versatile components in both residential and industrial contexts.

3. Quick Operation With a simple quarter-turn operation, ball valves allow for rapid start and stop flow control, which is crucial in emergencies or situations requiring quick changes in operation.

4. Low Resistance Because the flow path through a ball valve is straight, they offer low resistance, reducing the pressure drop in a system. This feature enhances the efficiency of systems where minimizing energy loss is essential.

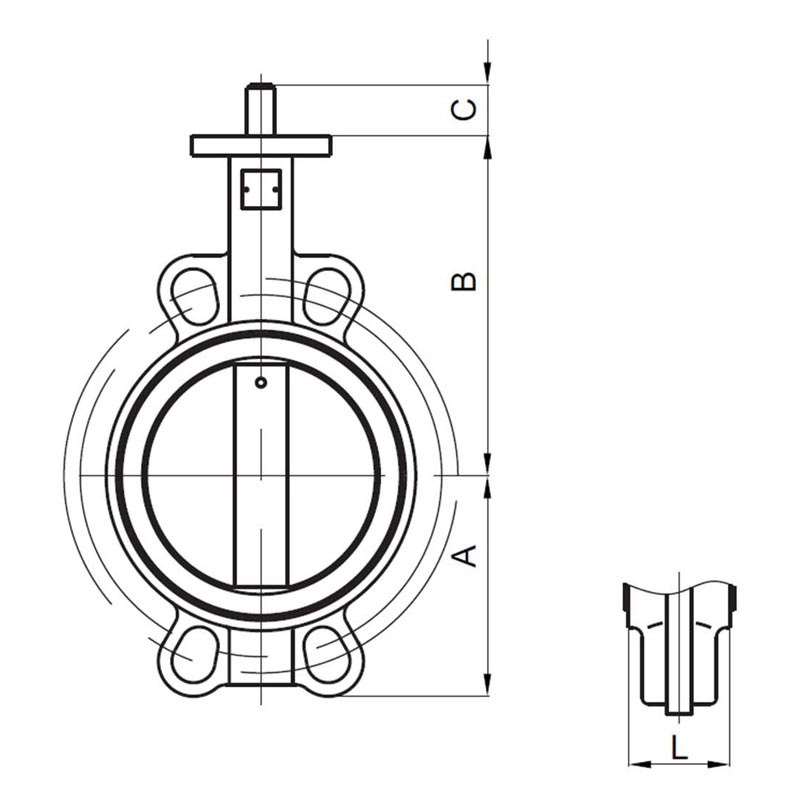

water ball valve

5. Minimal Maintenance Ball valves require little maintenance compared to other types of valves, partially due to their simple design and robust materials. Regular checks for wear and tear are typically sufficient to ensure optimal functioning.

Applications

Water ball valves find applications in a multitude of fields, ranging from residential plumbing to complex industrial systems. Common uses include

- Residential Plumbing Ball valves are often used as shut-off valves in water supply lines, allowing homeowners to control water flow easily for maintenance or emergencies. - Irrigation Systems In agriculture, ball valves manage the flow of water to irrigation systems, ensuring efficient water distribution. - Heating and Cooling Systems These valves regulate the flow of water in HVAC systems, crucial for maintaining desired temperatures in buildings. - Chemical Processing In industries dealing with chemicals, ball valves made from corrosion-resistant materials are essential for controlling the flow of liquids and preventing leaks. Maintenance Tips

While water ball valves are low-maintenance, a few simple practices can enhance their lifespan and efficiency

1. Regular Inspections Check for leaks or signs of wear periodically. Early detection of any potential issues can prevent more extensive damage.

2. Cleaning Dust and debris can accumulate around the valve area. Regular cleaning ensures smooth operation and prevents obstruction.

3. Lubrication In some cases, lubricating the handle mechanism can ensure smooth operation, especially in environments that experience temperature fluctuations.

4. Replacement of Worn Parts If leaks or malfunctions occur, assess if the ball or seat needs replacement rather than replacing the entire valve. This approach is typically more cost-effective.

In conclusion, water ball valves are indispensable in controlling fluid flow across various applications. Their durable design, ease of use, and versatility make them a preferred choice for both residential and industrial use. By understanding their functions, advantages, applications, and maintenance practices, users can ensure optimal performance and longevity of these critical components in water management systems.

Share