Aug . 28, 2024 11:31 Back to list

High-Quality Wafer Type Butterfly Valve Manufacturers | Reliable Solutions

Wafer Type Butterfly Valve Manufacturers A Comprehensive Overview

Butterfly valves are essential components in various industrial applications, known for their ability to regulate flow with minimal pressure drop. Among the different designs available, the wafer type butterfly valve stands out due to its unique characteristics and advantages. This article explores the realm of wafer type butterfly valve manufacturers, highlighting key aspects of their production and significance in the industry.

A wafer type butterfly valve is characterized by its compact design, which allows it to be sandwiched between two flanges in a piping system. This feature not only saves space but also reduces the overall weight of the valve, making it an ideal choice for applications where space and weight are critical factors. The simplicity of its design also contributes to its cost-effectiveness, appealing to a wide range of industries such as water treatment, chemical processing, and HVAC systems.

When it comes to wafer type butterfly valve manufacturers, several renowned companies are leading the way in innovation and quality. These manufacturers invest heavily in research and development to enhance the performance and longevity of their valves. They often use high-quality materials such as stainless steel, PVC, and other alloys, which provide excellent corrosion resistance and durability under various operating conditions.

One prominent manufacturer in the field is the Val-Matic Valve and Manufacturing Corporation. Known for its commitment to quality and reliability, Val-Matic specializes in a range of valve products, including wafer type butterfly valves. Their products are designed for both high-performance and ease of maintenance, ensuring that customers have reliable solutions for their flow control needs.

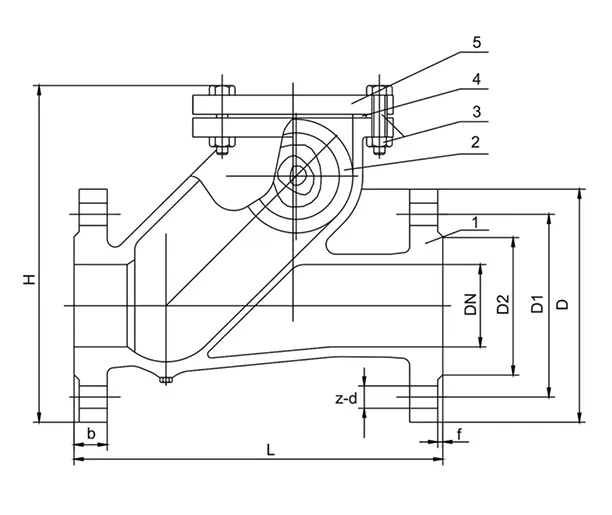

wafer type butterfly valve manufacturers

Another key player is the Bray International, Inc. They offer a wide array of wafer type butterfly valves characterized by innovative designs and features. Bray's valves are engineered for high efficiency, and they provide solutions suitable for the most challenging applications. Their focus on customer service also sets them apart, as they strive to meet client specifications and requirements diligently.

In recent years, the global demand for wafer type butterfly valves has surged, prompting manufacturers to expand their production capacities. The rise of automation and process control technology necessitates valves that can perform precisely under stringent conditions. As a response, manufacturers are developing advanced features such as actuators and control systems that integrate seamlessly with existing infrastructure.

Moreover, the impact of sustainability cannot be overlooked. Many manufacturers are now adopting eco-friendly practices in their production processes. They focus on reducing waste and energy consumption, which aligns with the growing emphasis on sustainability within various industries. This transition not only benefits the environment but also meets regulatory standards that are increasingly focused on minimizing environmental impact.

In summary, wafer type butterfly valve manufacturers play a critical role in modern industrial applications. With their space-saving design, cost-effectiveness, and adaptability to various conditions, these valves are indispensable in numerous sectors. As the industry continues to evolve, manufacturers remain at the forefront of innovation, producing high-quality products that meet the demands of a changing market. This dedication to excellence will ensure that wafer type butterfly valves remain a reliable choice for engineers and operators worldwide.

Share