Jan . 25, 2025 00:41 Back to list

trunnion mounted

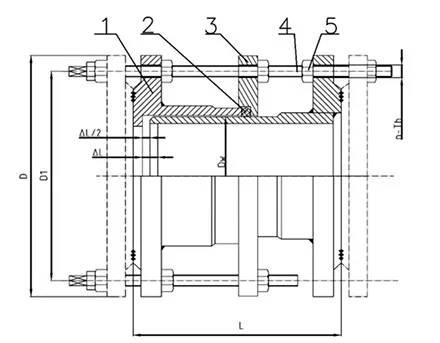

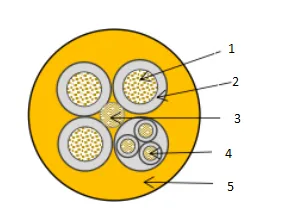

Trunnion mounted ball valves stand as a pivotal component across various industrial sectors, predicated on their unique design and comprehensive features. As businesses seek to enhance operational efficiency and reliability, understanding the intricacies of this equipment is paramount. Our exploration will unfold the dynamic capabilities of trunnion mounted designs, shedding light on their extensive application and technological advancements.

Safety is an intrinsic concern in industrial operations and trunnion mounted valves address this with advanced features such as fire-safe technology, anti-blowout stem designs, and pressure relief mechanisms. These safety enhancements are critical, ensuring the valves perform optimally even in unexpected exigencies. Documentation from various case studies confirms that these safety features reduce the likelihood of catastrophic failures, reassuring stakeholders about the dependability of these components. Training and expertise in handling trunnion mounted ball valves are crucial for maximizing their potential. Operators must be adept in installation techniques and maintenance routines specific to these valves. Comprehensive training modules, often offered by manufacturers, ensure that on-site personnel can optimize the performance and longevity of these valves. These programs also stress the importance of regular inspections and timely interventions, which are instrumental in preempting operational glitches. As environmental sustainability becomes a pressing concern, trunnion mounted valves also play a role in eco-friendly practices. Their efficient sealing capabilities minimize the risk of harmful emissions and fluid losses. Many manufacturers are now fabricating these valves with environmental compliance in mind, addressing both legislative and ethical demands for greener solutions. To sum up, trunnion mounted ball valves epitomize engineering excellence with their innovative design, materials, and advanced features. Their adoption across industries is a testament to their effectiveness in demanding applications. As technology progresses, these valves are set to become even more integral to industrial operations, offering robust, secure, and efficient flow control solutions. Engaging with cutting-edge trunnion mounted valve technologies not only aligns with industry best practices but also provides a competitive edge in today’s fast-paced industrial landscape.

Safety is an intrinsic concern in industrial operations and trunnion mounted valves address this with advanced features such as fire-safe technology, anti-blowout stem designs, and pressure relief mechanisms. These safety enhancements are critical, ensuring the valves perform optimally even in unexpected exigencies. Documentation from various case studies confirms that these safety features reduce the likelihood of catastrophic failures, reassuring stakeholders about the dependability of these components. Training and expertise in handling trunnion mounted ball valves are crucial for maximizing their potential. Operators must be adept in installation techniques and maintenance routines specific to these valves. Comprehensive training modules, often offered by manufacturers, ensure that on-site personnel can optimize the performance and longevity of these valves. These programs also stress the importance of regular inspections and timely interventions, which are instrumental in preempting operational glitches. As environmental sustainability becomes a pressing concern, trunnion mounted valves also play a role in eco-friendly practices. Their efficient sealing capabilities minimize the risk of harmful emissions and fluid losses. Many manufacturers are now fabricating these valves with environmental compliance in mind, addressing both legislative and ethical demands for greener solutions. To sum up, trunnion mounted ball valves epitomize engineering excellence with their innovative design, materials, and advanced features. Their adoption across industries is a testament to their effectiveness in demanding applications. As technology progresses, these valves are set to become even more integral to industrial operations, offering robust, secure, and efficient flow control solutions. Engaging with cutting-edge trunnion mounted valve technologies not only aligns with industry best practices but also provides a competitive edge in today’s fast-paced industrial landscape.

Share

Prev:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025