Nov . 09, 2024 07:24 Back to list

Durable Stainless Steel Globe Valve for Reliable Flow Control in Industrial Applications

Stainless Steel Globe Valves A Comprehensive Overview

In the realm of fluid control systems, stainless steel globe valves have emerged as a preferred choice due to their durability, reliability, and versatility. These valves are essential components in various industries, including oil and gas, water treatment, chemical processing, and power generation. This article delves into the key features, benefits, applications, and maintenance practices associated with stainless steel globe valves.

What is a Globe Valve?

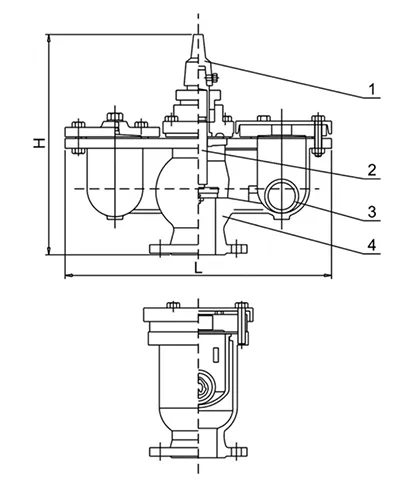

A globe valve is a type of valve used to regulate flow in a piping system. Its name derives from its spherical body shape, which houses a movable disc (or plug) that can be positioned to either block or allow fluid passage. The design of the globe valve provides a greater degree of flow control compared to other types of valves, such as gate or ball valves.

Advantages of Stainless Steel Globe Valves

1. Corrosion Resistance One of the most significant advantages of stainless steel globe valves is their excellent corrosion resistance. Stainless steel, particularly grades like 304 and 316, is highly resistant to rust and oxidation, making it ideal for handling corrosive fluids.

2. Temperature and Pressure Tolerance Stainless steel globe valves can withstand high temperatures and pressures, which is critical in industrial applications. Their robust construction enables them to function correctly under harsh conditions, ensuring reliability and longevity.

3. Flow Control Precision The design of globe valves allows for precise flow regulation. The disc can be finely adjusted to control the flow rate, which is essential in processes requiring specific fluid dynamics.

4. Durability Stainless steel is known for its strength and durability. Globe valves made from this material are less susceptible to wear and tear, leading to prolonged service life and reduced maintenance costs.

5. Versatility These valves are versatile and can be used for various applications across different industries, making them a popular choice for engineers and designers.

Applications of Stainless Steel Globe Valves

Stainless steel globe valves are widely used in numerous applications, including

- Oil and Gas Industry In the oil and gas sector, these valves control the flow of crude oil, natural gas, and various chemicals. They are essential for maintaining safe and efficient operations.

stainless steel globe valve

- Water and Wastewater Treatment Globe valves play a crucial role in managing water flow in treatment plants, ensuring that systems operate smoothly and efficiently

.- Chemical Processing In chemical plants, stainless steel globe valves regulate the flow of corrosive and hazardous substances, making safety and material resistance imperative.

- Power Generation Power plants utilize globe valves in various systems, including steam and cooling water systems, to maintain optimal performance and prevent leaks.

Maintenance of Stainless Steel Globe Valves

To ensure the longevity and optimal performance of stainless steel globe valves, regular maintenance is essential. Here are some best practices

1. Routine Inspections Regularly inspect the valves for signs of wear, corrosion, or leaks. Early detection of potential issues can prevent more significant problems down the line.

2. Lubrication Maintain proper lubrication of moving parts to ensure smooth operation. This is particularly important for the valve stem and packing.

3. Cleaning Keep the valve and surrounding area clean to prevent debris buildup that could impair function.

4. Functional Testing Perform periodic functional tests to ensure the valve operates correctly. This may include testing the valve's ability to open and close fully.

5. Replacement of Worn Components Replace any worn or damaged components, such as seals and gaskets, promptly to maintain the valve's integrity and performance.

Conclusion

Stainless steel globe valves are integral to fluid control in various industrial applications due to their unique combination of corrosion resistance, durability, and flow control capabilities. Understanding their advantages, applications, and maintenance needs is essential for engineers, operators, and maintenance personnel. By selecting the appropriate valve for specific needs and conducting regular maintenance, industries can ensure safe and efficient operations that stand the test of time. Investing in high-quality stainless steel globe valves makes good engineering sense, providing reliability and performance for years to come.

Share