Nov . 10, 2024 13:49 Back to list

Understanding the Functionality and Applications of Single Plate Check Valves

Understanding Single Plate Check Valves A Comprehensive Overview

In the realm of fluid mechanics and engineering, the efficient and reliable management of fluid flow is paramount. Among the various components used to regulate and direct fluids, the single plate check valve stands out for its simplicity and effectiveness. This article will delve into the features, benefits, applications, and maintenance of single plate check valves, helping you to understand why they are an essential component in many systems.

What is a Single Plate Check Valve?

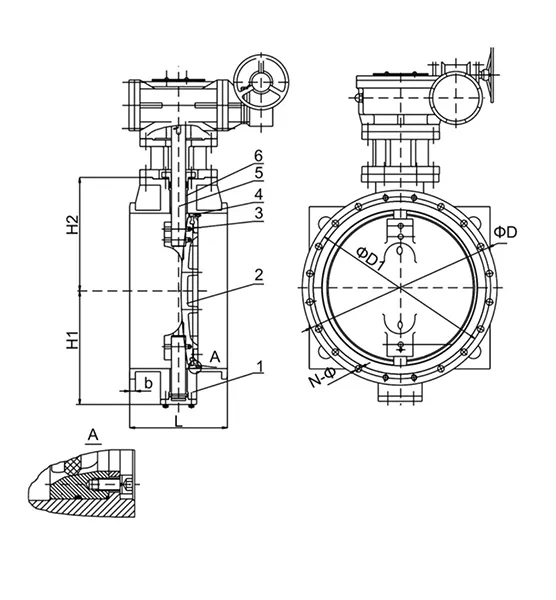

A single plate check valve is a type of mechanical device designed to allow fluid flow in one direction while preventing backflow. This function is achieved through the use of a single movable plate or disc that opens with forward flow and closes against a seat as flow attempts to reverse. The design is straightforward yet highly functional, making it a popular choice in many industrial applications.

Key Features

One of the most notable features of single plate check valves is their compact design. Their slim profiles mean that they require less space compared to other check valve types, such as swing check valves. This makes them particularly advantageous in installations with limited room. Additionally, the spring-loaded design of some models allows for quicker response times, minimizing the risk of water hammer—a pressure surge caused when fluid in motion is forced to stop or change direction suddenly.

Benefits of Single Plate Check Valves

1. Efficiency The single plate design ensures minimal pressure drop across the valve, allowing for efficient fluid flow. This can lead to energy savings and improved system performance.

2. Durability Made from high-quality materials such as stainless steel, bronze, or plastic, these valves are designed to withstand various harsh conditions, including temperature fluctuations and corrosive fluids.

3. Low Maintenance Single plate check valves have fewer moving parts than other valve types, resulting in reduced wear and tear; thus, they require less regular maintenance.

4. Versatility These valves can be used in a variety of applications, such as water treatment, HVAC systems, chemical processing, and more. Their adaptability makes them suitable for a wide range of industries.

Applications

single plate check valve

Single plate check valves are utilized in numerous applications where backflow prevention is critical. Some common scenarios include

- Pipelines They are often used in pipelines to allow water, oil, or gas to flow in one direction, preventing reverse flow which could lead to contamination or system failure. - Pumps In pump systems, they protect against backflow when the pump is turned off, ensuring that the system maintains its prime and preventing damage to equipment.

- Heating and Cooling Systems In HVAC applications, these valves help to manage the flow of heated or cooled air, enhancing system efficiency.

- Irrigation Systems They ensure that water flows in the desired direction, preventing contamination of the water supply.

Maintenance Considerations

While single plate check valves require minimal maintenance, regular inspections are essential to ensure optimum performance. Here are some tips for maintenance

- Visual Inspections Check for leaks, corrosion, or any signs of wear and tear.

- Functionality Tests Periodically test the valve's operation by observing its response to flow changes.

- Cleaning Remove any debris or build-up that may affect the valve's operation.

- Replacement If any parts are found to be defective, consider replacing them promptly to avoid system failures.

Conclusion

Single plate check valves are an integral component of many fluid systems, providing reliable backflow prevention with a compact and efficient design. Their numerous advantages, including low maintenance and versatility, make them a preferred choice for engineers and facility managers alike. Understanding how these valves work and their applications can help operators optimize their systems and ensure safety and efficiency in fluid management. As technology and designs evolve, the role of single plate check valves will undoubtedly continue to be crucial in maintaining fluid integrity across various industries.

Share