Nov . 18, 2024 02:08 Back to list

semi lugged butterfly valve

Understanding Semi-Lugged Butterfly Valves An Overview

Butterfly valves are essential components widely used in industrial applications for controlling the flow of fluids. Among the various configurations of butterfly valves, the semi-lugged butterfly valve stands out due to its unique design and functionalities. In this article, we will delve into the characteristics of semi-lugged butterfly valves, their applications, advantages, and maintenance considerations.

What is a Semi-Lugged Butterfly Valve?

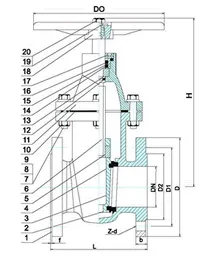

A semi-lugged butterfly valve is a specialized type of valve that features a body with semi-lugs—protrusions that enhance the valve's installation and maintenance capabilities. Unlike fully lugged butterfly valves, which have complete lugs extending around the valve body, semi-lugged designs provide a compromise between strength and accessibility. This feature makes them suitable for various industrial applications where space constraints and ease of maintenance are vital.

The core working principle of a butterfly valve involves a disc that rotates within the pipe. When the valve is opened, the disc aligns with the flow direction, allowing fluid to pass through freely. Conversely, rotating the disc perpendicular to the flow direction effectively blocks it. The semi-lugged design allows the valve to be mounted between flanges, providing flexibility in installation.

Key Features

1. Material Choices Semi-lugged butterfly valves can be manufactured from various materials such as cast iron, stainless steel, and PVC, making them versatile for different applications. The choice of material often depends on the fluid being transported and environmental conditions.

2. Size Range These valves come in an array of sizes, accommodating various pipeline dimensions. Their adaptability makes them suitable for both large-scale industrial operations and smaller applications.

3. Operating Mechanisms Semi-lugged butterfly valves can be operated manually or automatically. Automated versions often include pneumatic or electric actuation, enabling remote control and improving operational efficiency.

Applications

Semi-lugged butterfly valves are employed in a multitude of sectors, including

- Wastewater Treatment They regulate the flow of water and sewage in treatment facilities, ensuring efficient processing and minimizing backflow.

- Chemical Processing Their ability to handle corrosive substances makes them ideal for controlling the flow of various chemicals used in manufacturing processes.

semi lugged butterfly valve

- HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, these valves help manage airflow and pressure, contributing to system efficiency.

- Food and Beverage Industry Hygiene is crucial in food processing; thus, semi-lugged valves made from stainless steel are frequently used to minimize contamination risks.

Advantages

1. Space Efficiency The semi-lugged design allows for more compact installations, conserving valuable space in crowded environments.

2. Ease of Maintenance The semi-lugged feature facilitates easy removal and replacement without needing to dismantle adjacent piping, significantly reducing maintenance downtime.

3. Operational Versatility These valves can function effectively in both high and low-pressure systems, making them adaptable to various operational conditions.

4. Cost-Effectiveness Due to their durable construction and ease of maintenance, semi-lugged butterfly valves can be a more economical choice over time, providing long-term savings.

Maintenance Considerations

To ensure optimal performance and longevity of semi-lugged butterfly valves, regular maintenance is essential. This may include

- Visual Inspections Regularly checking the valve for signs of wear or damage can prevent unexpected failures.

- Lubrication of Moving Parts Ensuring that the operating mechanism is well-lubricated is crucial for smooth operation.

- Sealing Checks Periodically inspect seals for leaks, as a compromised seal can lead to inefficient operation.

In conclusion, semi-lugged butterfly valves play a crucial role in a variety of industrial applications. Their unique design offers an excellent balance of performance, ease of maintenance, and operational flexibility. By understanding their features and advantages, industries can make informed decisions when selecting the right valve for their specific needs, ultimately contributing to enhanced efficiency and productivity in their operations.

Share