Nov . 06, 2024 14:58 Back to list

Rubber Lined Butterfly Valve for Enhanced Performance and Durability in Fluid Control Systems

Rubber Lined Butterfly Valve A Comprehensive Overview

In the world of industrial applications and fluid management, valves play a crucial role in controlling the flow of liquids and gases. Among the various types of valves, the rubber lined butterfly valve stands out for its unique design and functionality. This article explores the characteristics, advantages, applications, and maintenance considerations for rubber lined butterfly valves.

What is a Rubber Lined Butterfly Valve?

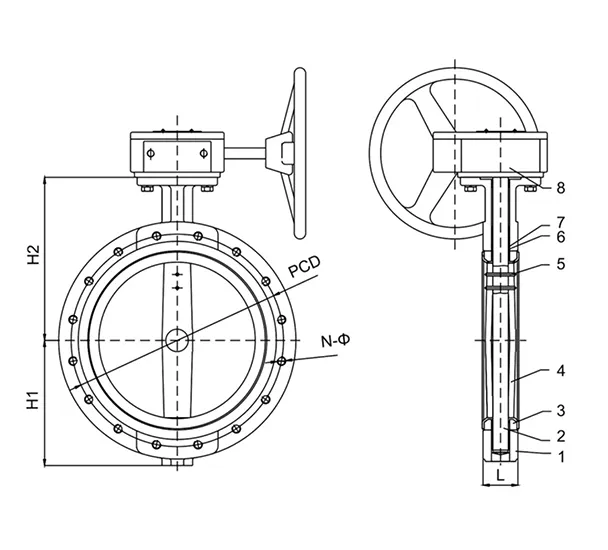

A rubber lined butterfly valve is a type of quarter-turn valve that consists of a circular disc or vane mounted on a rotating shaft. The valve is characterized by its rubber lining, which is applied to the valve body and the disc. This rubber lining is typically made of elastomers like EPDM, NBR, or neoprene, providing excellent resistance to corrosion, abrasion, and chemical damage. The design allows for a smooth and efficient flow control with minimal turbulence.

Characteristics of Rubber Lined Butterfly Valves

1. Design and Configuration The rubber lined butterfly valve features a streamlined design with fewer components than traditional valves, making it lightweight and easy to install. Its compact shape allows for space-saving in piping systems.

2. Operation The operation mechanism is simple. When the actuator (manual or automated) is turned, the disc rotates 90 degrees to either fully open or fully close the valve. This quarter-turn operation is efficient and quick, making it suitable for applications requiring rapid flow control.

3. Flow Control The rubber lining provides a tight seal when the valve is closed, preventing leaks and minimizing backflow. Moreover, the valve can be operated in both flow directions without any performance loss.

4. Temperature and Pressure Ratings Rubber lined butterfly valves can perform efficiently under various temperature and pressure conditions. However, the specific ratings depend on the type of rubber used, the valve design, and the manufacturer specifications.

Advantages of Rubber Lined Butterfly Valves

2. Versatility These valves can be used in various applications, from water treatment plants and sewage systems to chemical processing and food production. Their adaptability makes them a preferred choice in many industries.

rubber lined butterfly valve

3. Low Maintenance The design simplicity and durability of rubber lined butterfly valves contribute to lower maintenance requirements. Regular inspections and minor adjustments are usually sufficient to keep the valve functional.

4. Cost-effectiveness Given their durability and low maintenance needs, rubber lined butterfly valves often prove to be cost-effective in the long run compared to other types of valves.

Applications of Rubber Lined Butterfly Valves

1. Water and Wastewater Treatment These valves are commonly used in water distribution systems, sewage treatment plants, and industrial waste systems due to their corrosion resistance and reliability.

2. Chemical Processing In chemical plants, rubber lined butterfly valves are utilized for handling a wide range of corrosive media, ensuring safe and effective process control.

3. Food and Beverage Industry The rubber lining is often food-grade compliant, allowing these valves to be used in food processing applications where hygiene and safety are critical.

4. Pulp and Paper Industry The ability to withstand various chemicals makes rubber lined butterfly valves suitable for applications in the pulp and paper industry, where they control the flow of slurry and other substances.

Maintenance Considerations

While rubber lined butterfly valves are designed for durability, regular maintenance is essential to ensure optimal performance. Key maintenance practices include

- Routine Inspections Periodically checking for signs of wear, leaks, or damage to the rubber lining. - Cleaning Ensuring that the valve and its surroundings are clean to prevent build-up of debris, which may affect operation. - Lubrication Applying appropriate lubricants to moving parts to facilitate smooth operation.

Conclusion

In conclusion, rubber lined butterfly valves are indispensable components in various industrial applications due to their durability, efficiency, and versatility. By understanding their characteristics and maintaining them properly, industries can ensure reliable operation and prolonged service life, making them an excellent investment for fluid control needs.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025