Dec . 23, 2024 13:02 Back to list

Pneumatic Ball Valve Applications and Advantages in Industrial Automation Systems

Understanding Pneumatic Ball Valves Function, Applications, and Advantages

Pneumatic ball valves are essential components in various industrial applications, particularly in systems that require the regulation and control of fluid flow. These valves utilize a spherical disc, known as a ball, with a hole through the center to control the flow of gas or liquid. When the ball is rotated, it can either allow or block passage, making it a highly effective solution for on/off control. This article explores the function, applications, and advantages of pneumatic ball valves in modern industries.

Function of Pneumatic Ball Valves

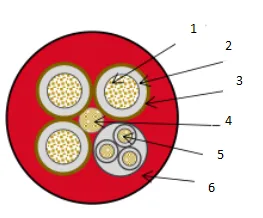

At the core of the pneumatic ball valve's operation is its simple yet effective design. The valve consists of a ball, a valve body, and a pneumatic actuator. The ball is typically located within the valve body and is connected to the pneumatic actuator. When the actuator receives a signal (often from a control system), it rotates the ball from a closed position (where the hole is perpendicular to the flow) to an open position (where the hole is aligned with the flow). This rotation allows the fluid to pass through the valve, effectively controlling the flow.

The response time of pneumatic ball valves is a significant advantage. Pneumatic systems can provide rapid opening and closing of the valve, which is crucial in applications that require precise control. Additionally, the design of the ball valve minimizes turbulence and pressure drop within the system, making it suitable for high-flow applications.

Applications of Pneumatic Ball Valves

Pneumatic ball valves find extensive use across various industries. Some of the most notable applications include

1. Water Treatment These valves are used in water treatment plants to control the flow of chemicals and ensure the proper treatment of water. They help in isolating sections of the system for maintenance and repairs.

2. Oil and Gas In the oil and gas sector, pneumatic ball valves are employed in pipelines to manage the flow of crude oil, natural gas, and refined products. Their reliability and ability to handle high pressures make them ideal for this industry.

3. Chemical Processing The chemical industry relies on ball valves for controlling the flow of reactive and corrosive substances. The integrity of the valve helps maintain safety and efficiency in chemical production processes.

4. Food and Beverage In the food and beverage industry, hygiene is paramount. Pneumatic ball valves made from sanitary materials are used to control the flow of liquids, ensuring compliance with health and safety regulations.

pneumatic ball valve

5. Pharmaceuticals In pharmaceutical production, precise flow control is critical. Pneumatic ball valves assist in maintaining strict quality control and ensuring the integrity of sensitive substances.

Advantages of Pneumatic Ball Valves

The use of pneumatic ball valves offers several advantages

- Quick Operation These valves can be operated quickly, allowing for rapid response times in critical applications. This is especially important in processes where delays can lead to inefficiencies or safety hazards.

- Compact Design Pneumatic ball valves have a compact design, which is essential in space-constrained environments. Their ability to fit into tight spaces without sacrificing functionality makes them appealing to engineers.

- Durability Made of robust materials, pneumatic ball valves are designed to withstand harsh operating conditions, including extreme temperatures and pressures. This durability extends the service life of the valve, reducing maintenance and replacement costs.

- Low Torque The design of the ball valve requires low torque to operate, meaning less energy is needed to open and close the valve. This characteristic makes pneumatic ball valves very efficient, contributing to lower operational costs.

- Versatility Pneumatic ball valves can be used with various fluids, including gases, liquids, and slurries. This versatility makes them suitable for a broad range of industries and applications.

Conclusion

Pneumatic ball valves play a crucial role in the efficiency and safety of fluid handling systems across multiple industries. Their simple design, quick operation, and robust characteristics make them ideal for applications ranging from water treatment to chemical processing. As industries continue to evolve, the demand for reliable and efficient control solutions like pneumatic ball valves will undoubtedly grow, reinforcing their importance in modern industrial automation.

Share