Nov . 10, 2024 12:57 Back to list

Durable Flexible Rubber Expansion Joints for Efficient Pipeline Solutions and Vibration Absorption

Understanding Flexible Rubber Expansion Joints Essential Components for Modern Engineering

In the realm of engineering, particularly in piping systems, the importance of flexible components cannot be overstated. One such crucial component is the flexible rubber expansion joint. These devices have become indispensable in various applications due to their ability to accommodate thermal expansion, movement, and vibration in piping systems. This article delves into the significance, functionality, and applications of flexible rubber expansion joints.

What Are Flexible Rubber Expansion Joints?

Flexible rubber expansion joints are specially designed components made primarily from elastomeric materials such as rubber. They are engineered to absorb movements caused by thermal expansion or contraction of piping systems, system vibrations, and lateral misalignments. These joints serve as a buffer, allowing pipes to move freely without stressing the connected sections, thereby prolonging the lifespan of the entire system.

Key Features and Benefits

1. Vibration Absorption One of the standout features of flexible rubber expansion joints is their ability to absorb vibrations. Many industrial processes generate significant vibrations which can lead to fatigue and failure in rigid piping systems. By using rubber expansion joints, engineers can significantly reduce the transmission of these vibrations, ensuring a smoother operation and minimizing wear on equipment.

2. Thermal Expansion Compensation As temperatures fluctuate, materials expand or contract. Flexible rubber expansion joints can accommodate these changes without causing damage to the pipes. This adaptability is critical in environments with extreme temperature variations, such as chemical processing plants or power generation facilities.

3. Ease of Installation Compared to rigid connectors, flexible rubber expansion joints are often easier to install. They allow for angular offsets and can accommodate slight misalignments, which can be particularly beneficial during the installation phase. This ease of installation can save time and labor costs, making them a preferred choice in many applications.

4. Corrosion Resistance Many rubber compounds used in expansion joints are resistant to various chemicals and environmental factors. This characteristic broadens their application range and protects the integrity of the piping system.

5. Maintenance-Free Once installed, flexible rubber expansion joints typically require minimal maintenance. Their durability and resistance to wear and tear contribute to their long service life, making them a cost-effective solution for many engineering applications.

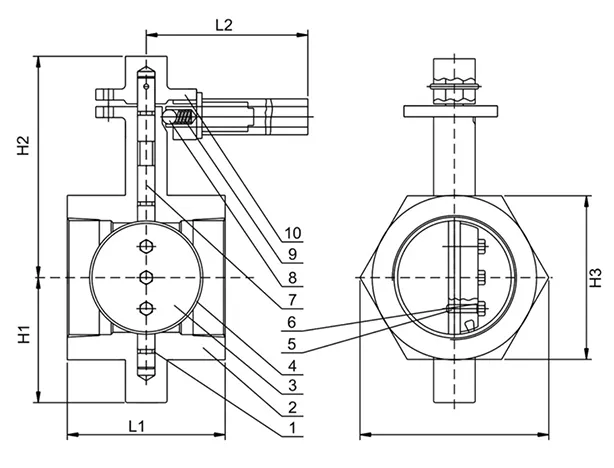

flexible rubber expansion joint

Applications of Flexible Rubber Expansion Joints

Flexible rubber expansion joints find their application in a myriad of industries, including

- Water and Wastewater Treatment They are commonly used in municipal water systems and wastewater treatment plants to accommodate the movement of pipelines and prevent leakage.

- HVAC Systems In heating, ventilation, and air conditioning systems, these joints help absorb vibrations from fans and motors while allowing for thermal expansion.

- Chemical Processing Due to their corrosion-resistant nature, rubber expansion joints are frequently utilized in chemical processing to manage the movement and expansion of pipes carrying corrosive substances.

- Power Generation In power plants, especially those that handle steam and hot water, these joints are essential for managing thermal expansion and reducing vibrations in piping systems.

- Oil and Gas The oil and gas industry also benefits from flexible rubber expansion joints to accommodate thermal expansion in pipelines transporting crude oil and natural gas.

Conclusion

Flexible rubber expansion joints are vital for the reliability and longevity of many modern engineering systems. Their ability to absorb vibrations, accommodate thermal expansion, and mitigate wear makes them an essential component in various industries. As technology advances and the demand for efficient and sustainable engineering solutions grows, flexible rubber expansion joints will undoubtedly continue to play a crucial role in the design and operation of piping systems worldwide. Their versatility, coupled with their ease of installation and maintenance, firmly establishes them as an indispensable asset in modern engineering practices.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025