Dec . 25, 2024 18:49 Back to list

EPDM Lined Butterfly Valves for Enhanced Performance and Durability in Various Applications

The Benefits of EPDM Lined Butterfly Valves A Comprehensive Overview

In the world of industrial applications, the choice of valves plays a pivotal role in ensuring the efficiency and safety of fluid handling systems. Among the various types of valves available, EPDM lined butterfly valves have gained significant attention due to their unique features and advantages. This article aims to delve into what EPDM lined butterfly valves are, their advantages, applications, and considerations for their use.

What are EPDM Lined Butterfly Valves?

Butterfly valves are quarter-turn valves that consist of a rotating disc to regulate flow. The EPDM (Ethylene Propylene Diene Monomer) lining is a crucial component of these valves, providing excellent resistance to a variety of chemicals, temperature extremes, and physical wear and tear. EPDM is a synthetic rubber that is renowned for its outstanding durability, flexibility, and resistance to aging, making it an ideal choice for valve applications in various industries.

Key Advantages of EPDM Lined Butterfly Valves

1. Chemical Resistance One of the primary benefits of EPDM lined butterfly valves is their impressive chemical resistance. EPDM can withstand a wide range of corrosive substances, making these valves suitable for diverse applications in the chemical, food and beverage, and wastewater industries. For example, they can effectively handle acids, bases, and various salts.

2. Temperature Tolerance EPDM lined valves can operate efficiently over a broad temperature range, typically from -40°F to +300°F (-40°C to +150°C). This flexibility allows them to be used in environments where traditional rubber materials would fail, ensuring reliable performance even under extreme conditions.

3. Low Friction and Quick Operation Butterfly valves are designed for rapid opening and closing, which is a critical feature for many industrial processes. The low frictional characteristics of the EPDM lining contribute to smoother operation, reducing the amount of torque required to turn the valve and facilitating faster response times.

4. Lightweight and Compact Design Compared to other valve types, butterfly valves are relatively lightweight and compact, making them easier to install and maintain. The design allows for efficient space usage in piping systems, an essential consideration in many facilities.

5. Cost-Effectiveness EPDM lined butterfly valves can be a more economical choice compared to other valve materials, especially when considering their long service life and low maintenance requirements. The durability of EPDM minimizes the need for replacements and repairs, providing significant cost savings over time.

Applications of EPDM Lined Butterfly Valves

EPDM lined butterfly valves are versatile and can be found in a range of applications, including

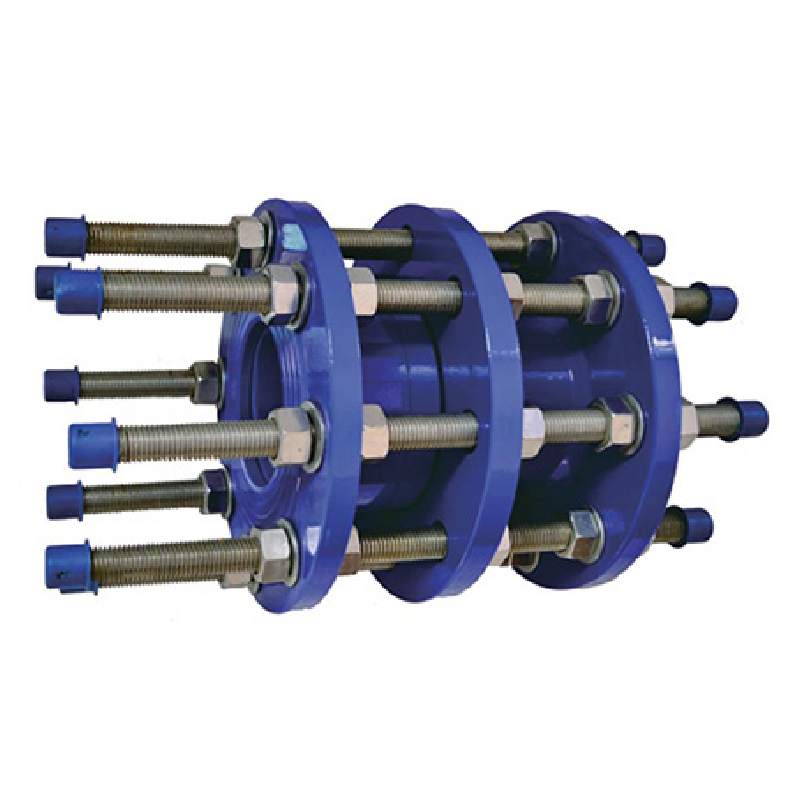

epdm lined butterfly valves

- Water Treatment These valves are commonly used in water and wastewater treatment plants, where their resistance to corrosive environments is crucial for maintaining the integrity of the systems.

- Food and Beverage In the food industry, EPDM is often used due to its compliance with food safety regulations. These valves can be utilized in processing, bottling, and distribution applications.

- Chemical Processing The chemical resistance of EPDM allows butterfly valves to handle various aggressive substances, making them indispensable in chemical manufacturing and transportation.

- HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, EPDM lined butterfly valves are employed to regulate airflow and maintain system efficiency.

Considerations When Using EPDM Lined Butterfly Valves

While EPDM lined butterfly valves offer numerous advantages, there are a few considerations to keep in mind

- Compatibility Ensure that the specific EPDM formulation is compatible with the fluids handled, particularly if any aggressive chemicals are present.

- Pressure Ratings Always adhere to the manufacturer's specifications regarding pressure ratings and temperature limits to ensure optimal operation.

- Installation and Maintenance Proper installation and regular maintenance are critical to prolonging the lifespan of EPDM lined butterfly valves.

Conclusion

EPDM lined butterfly valves represent a superior choice for many industrial applications thanks to their chemical resistance, durability, and efficiency. As industries continue to seek reliable and cost-effective solutions for fluid control, the demand for these valves is likely to grow. Understanding their features and applications can empower businesses to make informed decisions about their valve selection, ultimately enhancing operational efficiency and safety.

Share