Oct . 01, 2024 16:55 Back to list

Ductile Iron Metal Seat Gate Valve for Reliable Fluid Control Solutions

Ductile Iron Metal Seat Gate Valve An Overview

Ductile iron metal seat gate valves represent a significant advancement in valve technology, offering superior strength, durability, and performance in various industrial applications. These valves have become increasingly popular in sectors such as water treatment, oil and gas, chemical processing, and power generation due to their ability to maintain tight sealing and withstand extreme conditions.

What is a Ductile Iron Metal Seat Gate Valve?

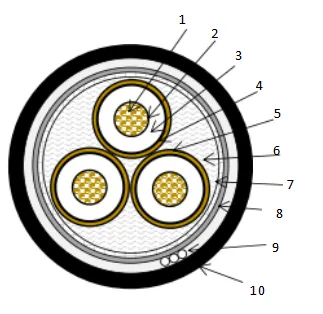

A gate valve is a type of valve that opens or closes by lifting a barrier (the gate) out of the path of the fluid. Ductile iron, also known as spheroidal graphite iron or nodular cast iron, is an alloy known for its excellent mechanical properties, including high tensile strength and ductility. The use of ductile iron in the construction of valve bodies provides enhanced resilience against cracking and impact, making it an ideal choice for high-pressure applications.

The term “metal seat” refers to the sealing surface of the valve, which is typically constructed from a durable metal rather than a softer material like rubber or plastic. This not only enhances the valve's ability to withstand higher temperatures and pressures but also ensures a longer lifespan with less maintenance compared to non-metal seat alternatives.

Advantages of Ductile Iron Metal Seat Gate Valves

1. Enhanced Durability Ductile iron is known for its toughness and resilience, enabling valves to endure harsh operating environments, including extreme temperatures and pressures. This durability translates to fewer replacements and maintenance interventions, leading to lower operating costs.

2. Tight Sealing The metal seat design allows for a secure seal, even under high pressure or temperature fluctuations. This feature is vital in preventing leaks, which can lead to safety hazards and increased operational costs.

3. Corrosion Resistance Many ductile iron valves come with protective coatings that enhance their resistance to corrosion and abrasion, making them suitable for a variety of applications, including wastewater treatment and chemical handling.

4. Versatility These valves can be used in a myriad of applications across different industries. Their ability to handle a wide range of fluids, including water, oil, gas, and chemicals, makes them highly versatile.

ductile iron metal seat gate valve

Applications in Various Industries

Ductile iron metal seat gate valves have found extensive applications across multiple sectors

- Water and Wastewater Treatment In municipal water systems, these valves are used to regulate water flow, ensuring efficient distribution and treatment. Their robust design makes them ideal for environments where handling abrasive materials is necessary.

- Oil and Gas In the oil and gas industry, durability and reliability are critical. Ductile iron gate valves are often used to control the flow of crude oil and natural gas, offering excellent performance even in extreme conditions.

- Chemical Processing The corrosion resistance of ductile iron valves makes them highly suitable for handling various chemicals, minimizing the risk of leaks that could compromise safety or lead to environmental hazards.

- Power Generation In power plants, these valves manage steam and water flow efficiently, contributing to the overall reliability and efficiency of energy production processes.

Conclusion

Ductile iron metal seat gate valves offer a combination of strength, durability, and versatility unmatched by other valve types. As industries continue to demand higher performance and reliability from their equipment, these valves will likely play an increasingly critical role in ensuring safe and efficient operations. With their ability to maintain tight seals and withstand harsh conditions, ductile iron metal seat gate valves are essential components in modern industrial infrastructure. As technology evolves, it is expected that innovations will further enhance their capabilities, solidifying their place as a preferred choice in the valve market.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025