Nov . 30, 2024 05:52 Back to list

High-Quality Ductile Iron Gate Valve for Optimal Flow Control Solutions

The Importance of Ductile Iron Gate Valves in Modern Applications

Ductile iron gate valves have grown in popularity within various industries due to their unique properties and superior performance. As a crucial component in controlling fluid flow, these valves are celebrated for their strength, durability, and resistance to corrosion. In this article, we will delve into the advantages of ductile iron gate valves, their applications, and the factors that make them an ideal choice for contemporary engineering and construction needs.

What is Ductile Iron?

Ductile iron, also known as ductile cast iron or spheroidal graphite iron, is a type of iron alloy that has enhanced mechanical properties compared to traditional cast iron. The microstructure of ductile iron contains spherical graphite nodules, which provide improved ductility and tensile strength. This makes ductile iron an ideal material for producing gate valves that require both strength and flexibility.

Advantages of Ductile Iron Gate Valves

1. Strength and Durability Ductile iron gate valves are characterized by their impressive strength, which enables them to withstand high pressure and extreme operating conditions. These valves can handle substantial mechanical stress without compromising their integrity, making them suitable for both industrial and municipal applications.

2. Corrosion Resistance The corrosion resistance of ductile iron can be enhanced through various coatings and finishes. When properly treated, ductile iron gate valves can resist the effects of water, wastewater, chemicals, and other corrosive media, significantly extending their lifespan.

3. Sealing Performance Gate valves are known for their ability to provide a tight seal. Ductile iron offers a smooth and robust surface for sealing, which minimizes leaks and ensures efficient operation. This characteristic is pivotal in applications where fluid containment is essential.

4. Versatility Ductile iron gate valves can be manufactured in various sizes and configurations, allowing them to be used in numerous applications, from water distribution systems to power plants. Their adaptability makes them a go-to solution for engineers and designers.

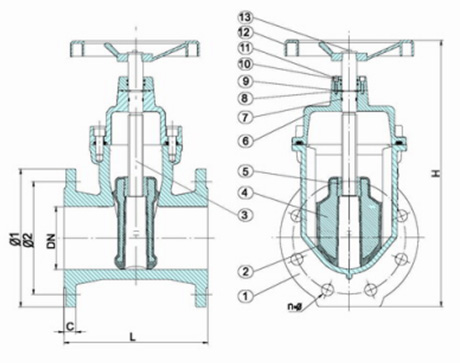

ductile iron gate valve

5. Cost-Effectiveness While the initial cost of ductile iron gate valves may be higher than that of traditional materials, their longevity and low maintenance requirements make them a cost-effective choice in the long run. The reduced need for frequent replacements and repairs translates to significant savings over time.

Applications of Ductile Iron Gate Valves

Ductile iron gate valves are utilized across a wide range of sectors, including

- Water Supply and Sewage Systems These valves play a crucial role in municipal water systems, allowing for the control and isolation of water flow, thereby facilitating maintenance and repairs without service disruption.

- Industrial Processes In various manufacturing industries, ductile iron gate valves are essential for regulating the flow of fluids in pipelines, ensuring optimal performance in processes that require precise control.

- Oil and Gas The energy sector heavily relies on the robust performance of ductile iron gate valves, especially in demanding environments where high pressures and various temperatures are common.

- Fire Protection Systems These valves are critical components in fire suppression systems, providing reliable shut-off capabilities to prevent the flow of water when not in use while allowing for swift action during emergencies.

Conclusion

Ductile iron gate valves have emerged as a vital component in modern infrastructure and industrial applications. Their superior strength, corrosion resistance, sealing capabilities, and versatility make them an excellent choice for engineers and facility managers. As industries continue to demand reliable and efficient solutions for fluid control, ductile iron gate valves will undoubtedly remain at the forefront of valve technology. Investing in these valves not only enhances operational efficiency but also ensures a reliable and sustainable future for various applications. As we look to the future, the role of ductile iron gate valves will only become more significant, driving innovations in fluid management systems worldwide.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025