Dec . 07, 2024 11:15 Back to list

dual plate check valve wafer type

Understanding Dual Plate Check Valves A Focus on Wafer Type

In industrial applications, the efficiency and reliability of fluid control systems are paramount. One of the crucial components used in these systems is the check valve, with the dual plate check valve being a popular choice for many engineers. This article delves into the dual plate check valve, particularly focusing on the wafer type, to understand its functionality, benefits, and applications.

What is a Dual Plate Check Valve?

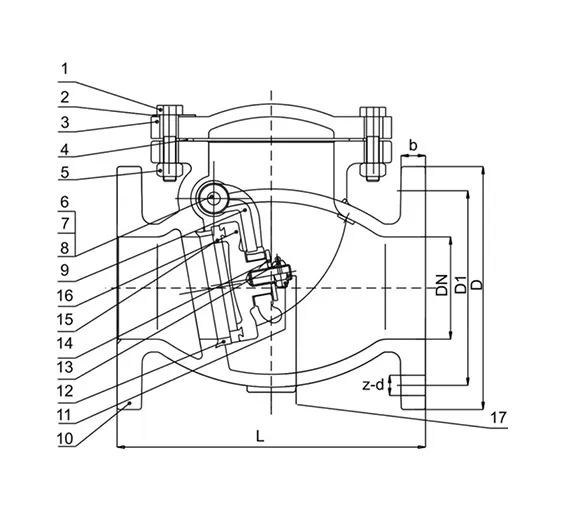

A dual plate check valve is a type of non-return valve designed to prevent backflow in piping systems. Unlike traditional swing check valves, the dual plate design features two plates (or discs) that open and close in response to fluid flow. When fluid flows in the forward direction, the plates open, allowing the flow to pass. Conversely, when the flow reverses, the plates quickly close, sealing the valve and preventing reverse flow. This design minimizes the possibility of water hammer—a phenomenon that can cause shock waves and damage within the pipeline.

Wafer Type Dual Plate Check Valves

The wafer type dual plate check valve is characterized by its compact, lightweight design. Unlike flanged or threaded check valves, wafer type valves are sandwiched between two flanges in a piping system, making installation simpler and less space-consuming. This design is particularly advantageous in applications where space is at a premium.

Wafer type dual plate check valves are generally made from various materials, including stainless steel, carbon steel, and cast iron, allowing for versatility based on the fluid being transported. The material selection plays a significant role in the valve's corrosion resistance, mechanical strength, and overall durability.

Advantages of Wafer Type Dual Plate Check Valves

1. Space Efficiency Their compact design is ideal for tight installations, making them suitable for a variety of applications where space savings are crucial. 2. Lightweight The lightweight nature of wafer type valves simplifies handling and installation, reducing labor costs and time.

3. Low Maintenance Due to their simple design, these valves generally require less maintenance compared to other types, contributing to lower operational costs.

dual plate check valve wafer type

4. Reduced Flow Resistance The streamlined design of dual plates minimizes turbulence and flow resistance, promoting more efficient fluid transport.

5. Versatile Applications Wafer type dual plate check valves are suitable for various industries, including water treatment, oil and gas, power generation, and HVAC systems.

6. Quick Response The dual plates provide a swift response to changes in flow direction, ensuring rapid sealing to prevent backflow.

Applications

Wafer type dual plate check valves are widely used in various applications, including

- Water Supply and Distribution Ensuring that water flows in one direction and preventing contamination from backflow in municipal systems. - Pumping Stations Protecting pumps from damage due to backflow, which can lead to cavitation and reduced efficiency.

- Fire Protection Systems Ensuring that fire suppression systems function effectively by preventing a reverse flow of water.

- HVAC Systems Maintaining proper airflow and protecting equipment from reverse flow in heating and cooling applications.

Conclusion

In summary, the wafer type dual plate check valve stands out as an essential component in modern fluid control systems. Its space-efficient design, lightweight nature, and low maintenance requirements make it an attractive option for various industries. Understanding the functionality and advantages of these valves allows engineers and facility managers to make informed decisions that enhance operational efficiency and safeguard their systems against potential issues. As industries continue to evolve, the role of dual plate check valves will remain significant in ensuring the seamless flow of fluids across a plethora of applications.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025