Nov . 05, 2024 01:15 Back to list

cast steel valve

The Advantages and Applications of Cast Steel Valves

In the field of industrial piping systems, valves play a critical role in controlling fluid flow. Among the various types of valves, cast steel valves have gained significant popularity due to their exceptional durability, reliability, and versatility in a wide range of applications. This article explores the advantages and applications of cast steel valves, highlighting why they are favored in many industries.

What are Cast Steel Valves?

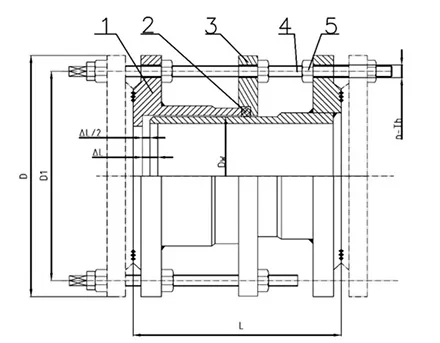

Cast steel valves are manufactured using a casting process where molten steel is poured into a mold to create the valve body. This method allows for the production of complex shapes and designs that are not easily achievable with other manufacturing techniques. Cast steel is known for its high strength and toughness, making it an ideal material for valves that must withstand high pressures and temperatures.

Advantages of Cast Steel Valves

1. Durability and Strength One of the primary benefits of cast steel valves is their exceptional strength. They can handle high-pressure environments and extreme temperatures without deforming or failing. This makes them suitable for a variety of demanding applications, including oil and gas, power generation, and chemical processing.

2. Corrosion Resistance While steel is not inherently corrosion-resistant, cast steel valves can be treated with various coatings or can be made from alloyed steel that includes elements like chromium and nickel, enhancing their resistance to corrosion and extending their lifespan.

3. Versatility Cast steel valves come in a variety of types, including gate valves, globe valves, check valves, and ball valves. This versatility allows them to be used in diverse applications across multiple industries. Whether for throttling flow, isolating a section of piping, or preventing backflow, there is likely a cast steel valve that fits the specific need.

cast steel valve

4. Ease of Maintenance The robust design of cast steel valves generally leads to lower maintenance requirements compared to other valve types. They are less prone to leakage and can be maintained easily through routine inspections and repairs. This translates to reduced downtime and lower operational costs.

5. Cost-Effectiveness Although cast steel valves may have a higher upfront cost compared to some other materials, their durability and low maintenance requirements result in a more economical solution in the long run. Their longevity means fewer replacements are needed, which can lead to significant savings over time.

Applications of Cast Steel Valves

Cast steel valves are utilized in a wide range of sectors.

- Oil and Gas Industry These valves are essential in drilling, production, and refining processes where control over the flow of hydrocarbons is critical. - Power Generation In power plants, cast steel valves are used in steam, water, and other fluid systems, where they manage the flow and pressure of high-temperature steam and water. - Chemical Processing The chemical industry relies on cast steel valves to handle corrosive and reactive fluids safely and effectively. - Water and Wastewater Treatment Cast steel valves are instrumental in water supply systems, helping to regulate water flow and maintain infrastructure integrity in treatment facilities. - Mining and Metallurgy In mining operations, these valves are used to control the flow of slurries and other materials in demanding environments.

Conclusion

In conclusion, cast steel valves are a vital component in modern industrial applications. Their durability, strength, corrosion resistance, versatility, ease of maintenance, and cost-effectiveness make them a preferred choice for industries looking to optimize their operations. As industries continue to evolve and face new challenges, the role of cast steel valves will undoubtedly remain significant in ensuring efficient and safe fluid control in various applications. As we move forward, investing in high-quality cast steel valves is not just a matter of compliance; it's a strategic decision that enhances operational efficiency and reliability.

Share