Nov . 18, 2024 10:53 Back to list

bidirectional knife gate valve

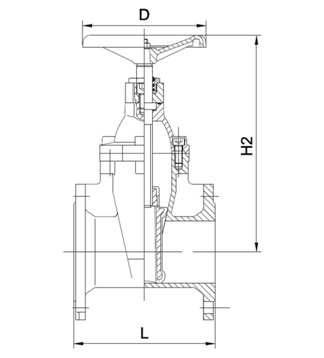

Understanding Bidirectional Knife Gate Valves A Comprehensive Overview

Bidirectional knife gate valves are crucial components in various industrial applications, particularly in the management of fluids and slurries. Known for their robust design and operational efficiency, these valves offer a reliable solution for controlling flow direction and isolation in piping systems. This article delves into the features, advantages, and applications of bidirectional knife gate valves, highlighting their significance in modern engineering.

What is a Bidirectional Knife Gate Valve?

A bidirectional knife gate valve is a type of valve that utilizes a sharp-edged gate (or knife) to cut through materials, making it particularly effective for slurries, viscous fluids, and solids in suspension. The term bidirectional indicates that the valve can operate effectively in both directions of flow, which enhances its versatility in various installations.

These valves are designed with a sliding gate that moves vertically, permitting flow when opened and blocking it when closed. Their construction typically involves a body made of durable materials such as cast iron, stainless steel, or other alloys, and they often feature a resilient, hard-faced blade that ensures effective sealing and longevity.

Key Features

1. Accessibility One of the main features of bidirectional knife gate valves is their ease of operation. These valves can be operated manually or automatically, allowing for seamless integration into existing control systems. Their design simplifies maintenance and inspection, reducing downtime during critical operations.

2. Robust Construction The materials used in the construction of knife gate valves are selected based on the specific applications. For example, corrosive environments may require stainless steel or special coatings, ensuring that the valve withstands harsh conditions.

3. Versatility Because they can function efficiently in both flow directions, bidirectional knife gate valves can be used in a wide range of applications, from wastewater treatment plants to mining operations. This flexibility is a significant advantage when designing fluid control systems.

4. Effective Sealing The unique design of the knife gate allows for a tight seal when closed. This feature is critical, particularly in applications where the prevention of leaks is essential, such as in chemical processing or sewage systems.

5. Low Leakage Rates Unlike some other valve types, bidirectional knife gate valves are designed to minimize the risk of leakages. Their clean-cut mechanism ensures that the seal is more effective, providing added safety and reliability in fluid management.

bidirectional knife gate valve

Advantages of Bidirectional Knife Gate Valves

- Cost-Effectiveness The durability and longevity of these valves lead to lower maintenance costs and reduced need for replacements. Thus, they prove to be a cost-effective choice over time.

- Efficiency in Slurry Applications The blade design permits the cutting through of dense slurries and hard materials efficiently. This makes them ideal for industries such as mining, where abrasive materials are common.

- Improved Flow Control With bidirectional flow capability, these valves can easily be incorporated into various systems, providing better overall flow management and operational efficiency.

Applications

1. Wastewater Treatment In wastewater systems, these valves are used to isolate different sections of the treatment facility, allowing operators to manage flow during maintenance or emergencies effectively.

2. Mining and Minerals Processing The ability to handle slurries and solid-laden fluids makes bidirectional knife gate valves an ideal choice in mining operations, where they control material flow from pumps and pipelines.

3. Food and Beverage Industry These valves are utilized in applications that require strict hygiene and efficient flow management, such as in the transport of coarse materials and slurries.

4. Chemical Processing With their robust construction, they are perfect for handling corrosive chemicals and ensuring that processes are carried out safely.

Conclusion

In summary, bidirectional knife gate valves serve as an essential component in various industries. Their unique design allows for effective management of fluids and slurries, making them a reliable choice for numerous applications. As technological advancements continue, the development of these valves is likely to progress, further enhancing their efficiency, versatility, and reliability in critical industrial processes. Understanding the significance and functionality of these valves is crucial for engineers and professionals involved in fluid management systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025