Sep . 22, 2024 01:08 Back to list

air pressure control valve

The Importance of Air Pressure Control Valve in Industrial Applications

Air pressure control valves are crucial components in various industrial applications, serving to regulate the pressure of air within pneumatic systems. These valves ensure that air pressure remains within specified limits, protecting equipment and enhancing the efficiency of operations. Understanding the functionality and importance of air pressure control valves can help industries optimize their systems for better performance and reliability.

Functionality of Air Pressure Control Valves

Air pressure control valves work by modulating the flow of compressed air to maintain a desired pressure within a system. They are equipped with sensors and actuators that monitor the pressure levels and adjust the valve opening accordingly. When the pressure exceeds a predetermined threshold, the valve partially closes to restrict airflow, and when the pressure drops below the desired level, the valve opens to allow more air in.

This functionality is crucial in pneumatic systems where consistent pressure is necessary for the proper operation of machinery. For example, in manufacturing plants, pneumatic tools and equipment rely on stable air pressure to function effectively. Fluctuations in pressure can lead to inefficient operation, increased wear and tear on equipment, and ultimately, costly downtime.

Key Benefits of Using Air Pressure Control Valves

1. Safety One of the primary benefits of air pressure control valves is the safety they provide. By maintaining pressure within safe limits, these valves help prevent hazardous situations that could lead to equipment failure or accidents in the workplace.

air pressure control valve

2. Efficiency Properly managed air pressure contributes to the overall efficiency of pneumatic systems. Air pressure control valves minimize air wastage by ensuring that only the necessary amount of compressed air is used, which can lead to significant cost savings over time.

3. Durability of Equipment Minimizing pressure fluctuations helps extend the lifespan of pneumatic tools and equipment. Excessive pressure can cause damage or premature wear, leading to increased maintenance costs and the need for frequent replacements.

4. Improved Productivity When air pressure is consistently maintained, machinery operates at optimal performance, leading to increased productivity. Workers can rely on their tools to function without interruptions caused by pressure-related issues.

5. Customizability Many modern air pressure control valves offer customizable settings to suit specific industrial needs. This flexibility allows industries to tailor their pneumatic systems according to the unique requirements of their operations.

Conclusion

In summary, air pressure control valves are vital for ensuring the safety, efficiency, and reliability of pneumatic systems across various industries. By regulating air pressure, these valves protect equipment, enhance productivity, and reduce operational costs. As technology continues to advance, the role of air pressure control valves will likely expand, offering even more sophisticated solutions to the challenges faced in industrial environments. Proper selection, installation, and maintenance of these valves can significantly impact the overall success of an organization’s operational processes. As industries move towards greater automation and efficiency, investing in quality air pressure control valves will remain a cornerstone of effective pneumatic systems.

Share

-

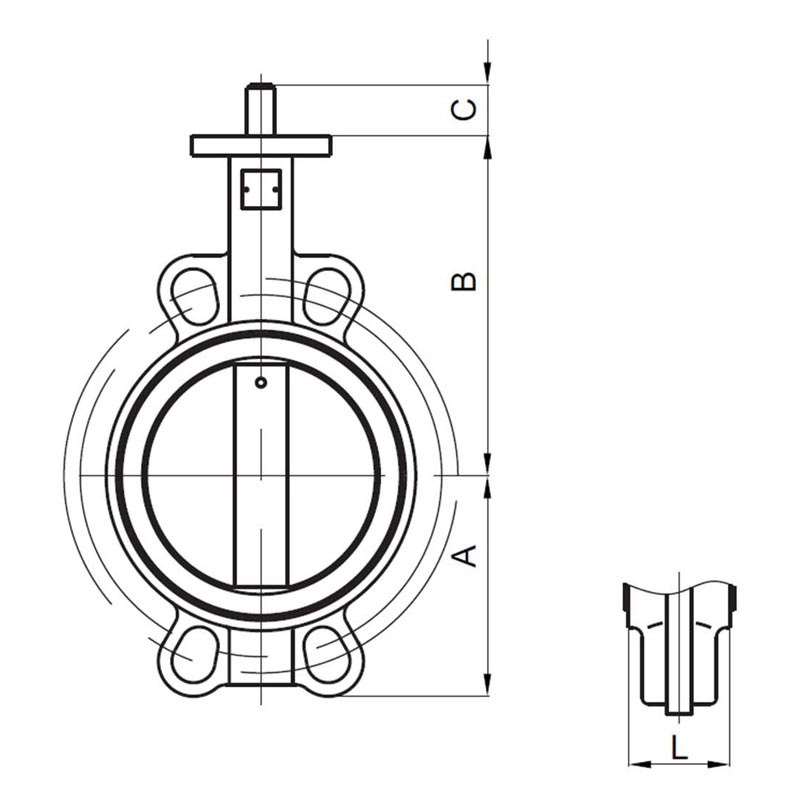

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025