Nov . 22, 2024 09:50 Back to list

swing check valve 6 inch

Understanding the 6-Inch Swing Check Valve An Essential Component in Fluid Dynamics

In today's rapidly advancing industrial landscape, the need for efficient and reliable fluid control mechanisms is paramount. One such component that plays a crucial role is the swing check valve, particularly the 6-inch variant. This device is vital for preventing backflow in piping systems and ensuring the smooth operation of various applications across multiple sectors, including water supply, sewage systems, and industrial processes.

What is a Swing Check Valve?

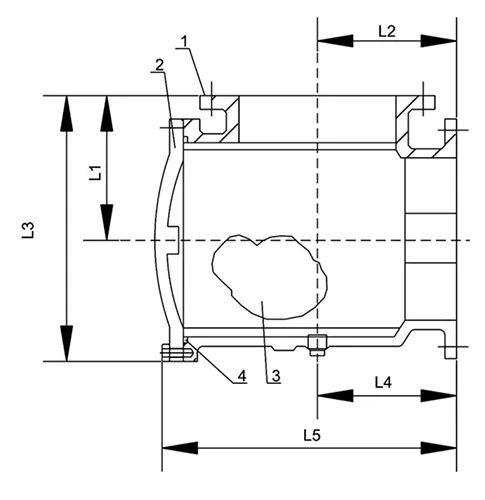

A swing check valve is a type of one-way valve that allows fluid to flow in a single direction. The design typically features a hinged disc that swings open when fluid flows in the intended direction and closes as the flow reverses, preventing any backflow. This mechanism is especially beneficial in systems where backpressure is a concern, making it an essential part of many fluid distribution networks.

Key Features of the 6-Inch Swing Check Valve

1. Size and Flow Capacity The 6-inch size indicates the nominal diameter of the valve, which is suitable for medium to large piping systems. This size allows for significant flow capacity, making it ideal for industrial applications where large volumes of fluid need to be managed efficiently.

2. Materials Swing check valves can be made from various materials, including cast iron, stainless steel, and PVC. The choice of material often depends on the specific application and the types of fluids being transported. For instance, stainless steel valves are preferred for corrosive fluids, while cast iron may be used in non-corrosive environments.

3. Installation and Maintenance The installation of a swing check valve is straightforward, typically requiring flanged connections that facilitate easy integration into existing piping systems. Maintenance is also relatively easy, as these valves are designed to be resilient and require minimal intervention. Regular inspections and cleaning can help maintain optimal performance over time.

4. Operating Principles The operation of the swing check valve relies on the principles of fluid dynamics. When the pressure in the pipeline increases (such as when a pump is activated), the disc swings open, allowing the fluid to flow. Once the flow ceases or reverses, gravity and the weight of the disc cause it to swing back, sealing the opening and preventing any undesired backflow.

swing check valve 6 inch

Applications of 6-Inch Swing Check Valves

6-inch swing check valves are utilized in various industries, including

- Water Treatment Facilities They are essential for ensuring the proper flow of water and preventing backflow in treatment processes. - Sewage Systems In sewage systems, these valves help maintain the integrity of flow, preventing contamination from backflow. - Industrial Processes In manufacturing and processing plants, these valves are used in various piping systems to control the direction of fluid flow. - Fire Protection Systems They ensure that the water used in fire suppression systems flows properly without risk of backflow into the municipal system.

Advantages of Using Swing Check Valves

The use of swing check valves, especially the 6-inch variants, comes with several advantages

- Efficiency They provide a reliable means of preventing backflow, which is critical for maintaining fluid integrity in various applications. - Cost-Effectiveness Given their durability and low maintenance requirements, these valves offer long-term savings in operational costs. - Versatility They can handle a wide range of fluids, including water, oils, and chemicals, making them suitable for diverse applications.

Conclusion

In summary, the 6-inch swing check valve is a vital component in modern fluid control systems. Its design and functionality not only ensure the efficient management of fluid flows but also safeguard against the risks associated with backflow. Businesses and industries that rely on consistent fluid dynamics can benefit immensely from integrating these valves into their systems, ensuring operational efficiency and safety in their processes. As industrial applications continue to evolve, the importance of reliable mechanisms like swing check valves will only grow, further reinforcing their status as essential tools in engineering and infrastructure development.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025