Dec . 06, 2024 06:54 Back to list

Ball Valve and Y Strainer Combination for Efficient Fluid Control

Understanding Ball Valves with Y Strainers A Comprehensive Overview

When it comes to fluid control in various industrial applications, the importance of using quality components cannot be overstated. Among these essential components, ball valves paired with Y strainers stand out for their efficiency and reliability. In this article, we will explore the functionality, benefits, and applications of ball valves with Y strainers, as well as considerations for their selection and maintenance.

What is a Ball Valve?

A ball valve is a type of quarter-turn valve that uses a spherical disc (the ball) to control the flow of liquid or gas. The ball has a hole through the center, which allows for fluid passage when aligned with the flow direction. When the ball is rotated perpendicular to the flow, the valve is sealed, effectively stopping the flow. The design of ball valves allows for quick operation, minimal pressure drop, and a tight seal, making them suitable for various applications.

What is a Y Strainer?

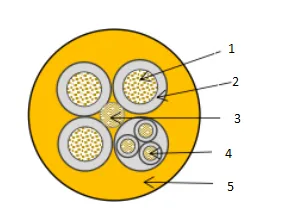

A Y strainer is a type of filtration device commonly used to remove debris and particles from fluids flowing through pipes. Named for its distinctive Y shape, this strainer is typically installed in pipelines to protect essential equipment, including valves and pumps, from potential damage caused by foreign materials. The strainer features a removable mesh screen, which captures particles while allowing clean fluid to pass through.

The Synergy of Ball Valves and Y Strainers

Combining a ball valve with a Y strainer creates a comprehensive solution for fluid control and cleanliness. The ball valve offers tight shutoff and flow control, while the Y strainer prevents clogging and wear on the valve and downstream equipment. This synergy ensures that the system operates efficiently, extends the lifespan of components, and reduces maintenance needs.

Key Benefits

1. Improved Protection The Y strainer acts as a barrier against unwanted particulates that could damage the ball valve and other downstream equipment. This protection is crucial in applications where the fluid may carry sediment or debris.

2. Enhanced Flow Control The use of a ball valve allows for precise control over the flow rate, enabling operators to adjust conditions according to the specific requirements of the process.

ball valve with y strainer

3. Easy Maintenance Both the ball valve and the Y strainer are designed for ease of maintenance. The Y strainer can be quickly cleaned or replaced without significant downtime, preserving the overall efficiency of the system.

4. Versatility This combination is suitable for a wide range of applications, from water treatment facilities to oil and gas pipelines. Their ability to handle high pressures and temperatures makes them an attractive option for various industries.

Applications

Ball valves with Y strainers are used in diverse industries, including

- Water Treatment To ensure clean water by filtering out impurities and maintaining optimal flow control in treatment plants. - Chemical Processing To protect sensitive equipment from corrosion and degradation caused by contaminants in the chemicals being processed. - HVAC Systems To maintain efficient airflow and prevent blockages in heating, ventilation, and air conditioning systems.

Considerations for Selection and Maintenance

When selecting a ball valve with a Y strainer, consider the following factors

- Material Compatibility Ensure that the materials of both the valve and strainer are compatible with the fluids being handled to prevent chemical reactions or degradation. - Pressure and Temperature Ratings Verify that the components can withstand the specific pressure and temperature conditions of the application. - Strainer Mesh Size Choose an appropriate mesh size based on the expected particle size of the contaminants in the fluid.

For maintenance, regular inspections should be carried out to check for signs of wear, clogging, or corrosion. Cleaning the Y strainer screen and testing the ball valve's operation can help avoid unexpected failures and prolong equipment lifespan.

Conclusion

Incorporating ball valves with Y strainers into fluid control systems enhances performance, increases reliability, and provides effective protection against debris. With a thorough understanding of their functionality and benefits, operators can make informed decisions that lead to more efficient and sustainable operations.

Share