డిసెం . 29, 2024 12:45 Back to list

resilient gate valve

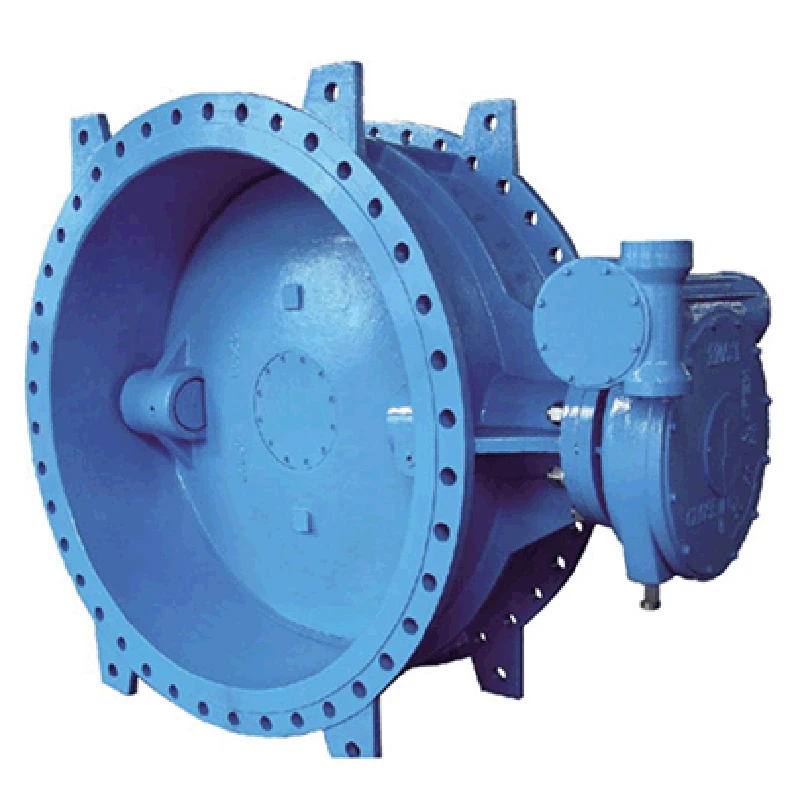

Resilient Gate Valve An Essential Component in Modern Pipelines

The resilient gate valve has emerged as a critical component in various industrial applications, particularly in water supply, wastewater management, and various fluid control systems. This valve type combines the traditional functionality of a gate valve with modern materials and design innovations, leading to enhanced reliability and performance. In this article, we will explore the features, benefits, applications, and maintenance of resilient gate valves.

What is a Resilient Gate Valve?

A resilient gate valve is a type of valve used to start or stop the flow of fluids in a pipeline system. Unlike traditional metal gate valves, which rely on a rigid wedge, resilient gate valves utilize a flexible elastomeric material for the seal. This design allows for a more effective shut-off and reduces the possibility of leakage. The gate operates by moving up and down in the valve body, providing a straight-line flow path when fully open, which minimizes turbulence and pressure drop.

Key Features

1. Materials and Design Resilient gate valves are typically made from ductile iron, which provides strength and durability. The sealing elements are made from high-quality elastomers like EPDM or neoprene, ensuring a tight seal even under varying pressure conditions.

2. Ease of Operation These valves are designed for easy operation, often featuring handwheel or electric actuator options. The design reduces the force required to open and close the valve, making it user-friendly.

3. Corrosion Resistance Many resilient gate valves come with corrosion-resistant coatings, such as epoxy, which prolongs their lifespan and ensures reliable performance in harsh environments.

4. Versatility Resilient gate valves are suitable for various applications, including drinking water distribution systems, sewage treatment plants, and industrial water processes. Their ability to handle both dirty and clean fluids makes them versatile in usage.

5. Minimal Maintenance With fewer moving parts and a robust design, resilient gate valves require minimal maintenance compared to their traditional counterparts. Regular inspections should suffice to ensure their longevity and efficiency.

Benefits of Resilient Gate Valves

- Leakage Prevention The innovative design and materials reduce the risk of leakage, protecting the environment and conserving resources in water supply systems.

- Durability Constructed from resilient materials, these valves can withstand the rigors of fluctuating pressures and temperatures, ensuring a longer service life.

- Cost-Effectiveness Although the initial investment may be slightly higher, the reduced maintenance, installation costs, and longevity of resilient gate valves yield significant savings over time

.resilient gate valve

- Improved Performance The fluid dynamics provided by a fully open gate facilitate better flow characteristics, leading to enhanced system efficiency.

Applications

Resilient gate valves are utilized across a range of sectors, including

- Water Distribution Essential for municipal water systems, these valves control the flow and ensure the reliability of water supply to residential and commercial areas.

- Wastewater Treatment In treatment facilities, resilient gate valves help manage the flow of wastewater, playing a crucial role in the treatment process.

- Industrial Processes Many industries, including oil and gas, pharmaceuticals, and food processing, rely on resilient gate valves for their durability and performance under demanding conditions.

Maintenance Considerations

To maximize the lifespan and efficiency of resilient gate valves, consider the following maintenance practices

- Regular Inspections Conduct routine inspections to check for signs of wear, corrosion, or leaks.

- Exercise the Valve Regularly operate the valve to prevent it from seizing due to inactivity.

- Monitor Pressure and Flow Keep an eye on any unusual changes in pressure or flow rates, which could indicate valve issues.

- Cleaning Ensure that the valve and its surrounding area are free of debris that could impede operation.

Conclusion

In conclusion, the resilient gate valve represents a significant advancement in valve technology, blending traditional functions with modern materials and designs. Their robust performance, ease of maintenance, and versatility make them an indispensable component in many fluid control systems. As industries continue to prioritize efficiency and reliability, the resilient gate valve will undoubtedly play a crucial role in meeting these demands. Whether in water distribution, wastewater treatment, or industrial applications, understanding and utilizing resilient gate valves can lead to enhanced operational performance and resource conservation.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025