நவ் . 15, 2024 11:20 Back to list

metal seat gate valve

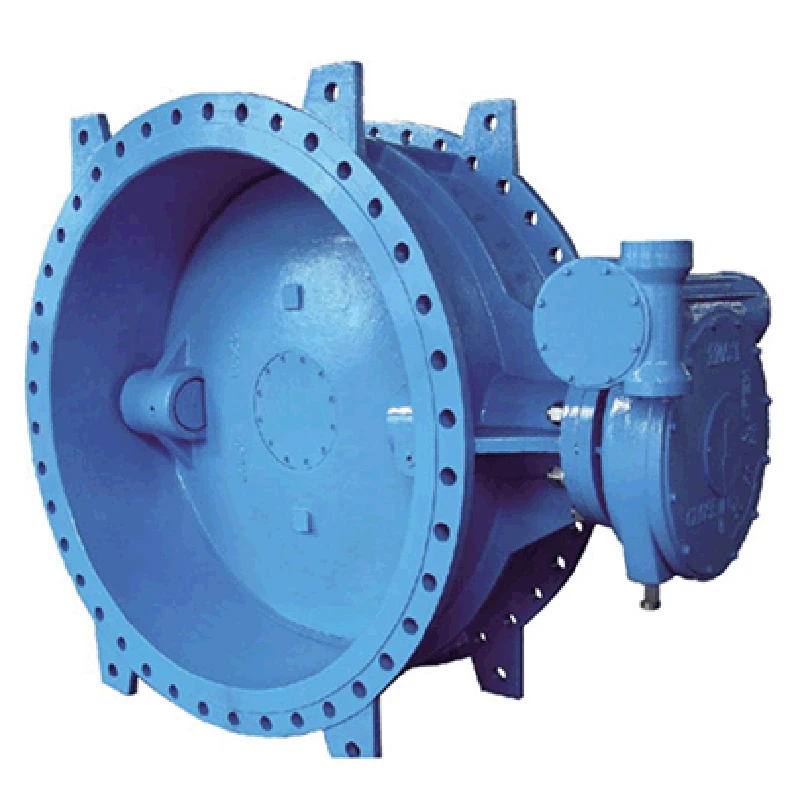

Understanding Metal Seat Gate Valves Functionality and Applications

Metal seat gate valves are essential components in various industrial applications, most notably in sectors dealing with high pressures and temperatures, such as oil and gas, water treatment, and chemical processing. These valves are designed to control the flow of liquids and gases with precision, ensuring optimal performance under demanding conditions.

What are Metal Seat Gate Valves?

A gate valve is a type of valve used to start or stop fluid flow. Unlike other types of valves, which regulate flow, gate valves are designed to be either fully open or fully closed. Metal seat gate valves refer to those that feature a metal-to-metal seating arrangement, which provides superior durability and longevity compared to traditional soft-seated valves. This design is particularly advantageous in high-pressure and high-temperature environments, where soft seats can wear out quickly and lead to leaks.

Key Features and Benefits

1. Durability The use of metal seating allows these valves to withstand extreme temperatures and pressures, making them ideal for harsh industrial environments.

2. Tight Sealing Metal seat gate valves provide excellent sealing capabilities. When fully closed, they prevent leakage, ensuring that the system maintains its integrity.

3. Low Flow Resistance The design of gate valves allows for a straight-through flow path, minimizing resistance and turbulence. This characteristic is particularly important in applications where maintaining a steady flow rate is crucial.

4. Versatility These valves are suitable for various media types, including corrosive substances, thanks to the robust materials used in their construction.

metal seat gate valve

5. Ease of Maintenance Metal seat gate valves generally require less maintenance than their soft-seated counterparts due to their sturdiness. When needed, repairs are typically straightforward, significantly reducing downtime.

Applications

Metal seat gate valves are found in numerous applications across different industries

- Oil and Gas They are widely used in pipelines and storage facilities to control the flow of crude oil, natural gas, and refined products. Their ability to handle high pressures is critical in this sector.

- Water Treatment In water treatment plants, metal seat gate valves help control the flow of water during processing, purification, and distribution.

- Power Generation These valves play a crucial role in steam and cooling systems within power plants, regulating the flow of water and steam and contributing to efficient energy production.

- Chemical Processing In chemical plants, metal seat gate valves are used to manage the flow of various chemicals, many of which are corrosive and require robust materials to ensure safety and reliability.

Conclusion

In summary, metal seat gate valves are vital components in many industries where reliability and durability are paramount. Their robust design, sealed integrity, and low maintenance requirements make them an excellent choice for controlling fluid flow in critical applications. As industries continue to evolve, the demand for efficient and reliable valves like metal seat gate valves will undoubtedly increase, ensuring their place in the future of industrial operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025