Novemba . 05, 2024 07:26 Back to list

y strainer ansi 150

Understanding Y-Strainers and ANSI 150 Standards

In various industrial applications, the integrity and performance of fluid systems are crucial. A significant component that plays a vital role in ensuring smooth operations is the Y-strainer. This article focuses on Y-strainers, particularly those designed to meet ANSI 150 standards, which are essential for various piping systems used in different sectors such as water treatment, oil and gas, and chemical processing.

What is a Y-Strainer?

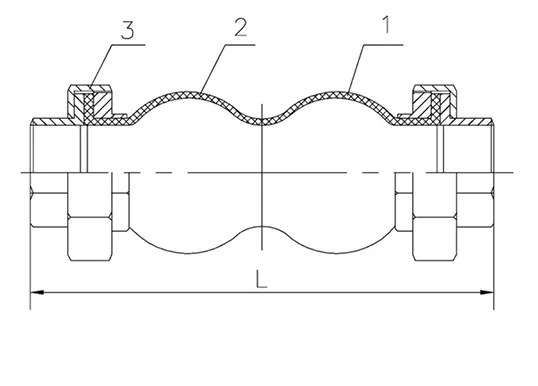

A Y-strainer is a specific type of strainer designed to filter out debris and particulate matter from liquid or gas flow. Its name derives from its characteristic shape, resembling the letter Y. Y-strainers are typically installed inline within a piping system to prevent contaminants from damaging pumps, valves, and other critical components. They are particularly effective in applications involving water, oil, and various chemicals.

The Y-strainer consists of a cylindrical body, typically made from materials such as stainless steel, carbon steel, or plastic. Inside the body, a filter element is housed, which catches particulates while allowing fluids to pass through. They can have different mesh sizes, depending on the application and the size of the particles to be filtered.

ANSI 150 Standards

The American National Standards Institute (ANSI) has established several standards to promote safety, reliability, and efficiency in industrial practices. The ANSI 150 standard refers to a pressure rating for piping components including valves, flanges, and fittings in a given system. Components that adhere to ANSI 150 standards can operate effectively at a pressure level of up to 150 pounds per square inch (psi) at specific temperatures.

The ANSI 150 standard is commonly applied in various industries, where standardized pressure ratings ensure compatibility and reliability between different components. One of the primary benefits of adhering to these standards is that it allows engineers and operators to confidently select compatible components, ensuring safety and stability in operations.

The Importance of Using ANSI 150 Compliant Y-Strainers

y strainer ansi 150

Using Y-strainers that comply with ANSI 150 standards is crucial for several reasons. Firstly, compliance ensures that the strainer can withstand the pressures and conditions typically encountered in various industrial applications. Having a Y-strainer rated for ANSI 150 means it is designed to withstand the damage that could result from fluctuations in pressure or undesired backflow.

Secondly, ANSI 150 compliant Y-strainers facilitate easier integration within existing piping networks that already meet ANSI standards. This compatibility reduces the risk of leaks or failures that could arise from using non-standard parts in a standardized system.

Lastly, using high-quality Y-strainers benefits maintenance routines. These strainers are often designed for easy access and cleaning, ensuring that they can be routinely inspected and serviced. This maintenance is vital for preventing blockages that could disrupt operational flow and lead to costly downtime.

Applications of ANSI 150 Y-Strainers

ANSI 150 Y-strainers can be found in various applications, including but not limited to

1. Water Treatment Plants In these facilities, Y-strainers remove sediments and debris from water before it undergoes treatment, ensuring that the systems remain efficient and reliable. 2. Chemical Processing In chemical manufacturing, Y-strainers are essential for protecting sensitive equipment by filtering out particles that could spoil reactions or damage machinery. 3. Oil and Gas Industry Here, Y-strainers help maintain the integrity of pipelines by preventing the ingress of foreign contaminants that could disrupt the smooth operation of extraction and refining processes.

Conclusion

In conclusion, Y-strainers are vital components for maintaining the efficiency and safety of various fluid systems across multiple industries. By adhering to ANSI 150 standards, these strainers ensure reliability and compatibility within piping networks. Incorporating ANSI 150 compliant Y-strainers into industrial systems not only enhances operational efficiency but also safeguards critical equipment, ultimately contributing to the overall success of industrial operations. Proper selection, installation, and maintenance of these strainers can significantly reduce downtime and operational risks, making them an indispensable part of fluid handling systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025