Desemba . 10, 2024 01:37 Back to list

Wafer Style Silent Check Valve for Efficient Fluid Control Solutions

Understanding Wafer Type Silent Check Valves

In the realm of fluid control systems, the significance of valves cannot be overstated. Among the various types of valves, wafer type silent check valves stand out for their unique design and performance characteristics that make them indispensable in numerous applications. This article delves into the fundamental features, applications, advantages, and considerations associated with wafer type silent check valves.

What is a Wafer Type Silent Check Valve?

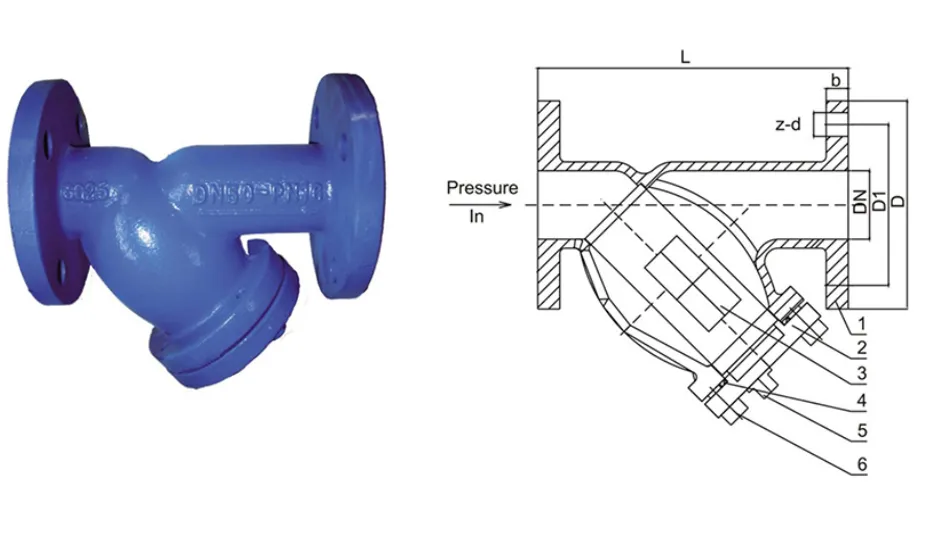

A wafer type silent check valve is a specialized valve designed to prevent backflow in piping systems. It consists of a disc placed on a hinge, which allows fluid to flow in one direction while preventing reverse flow. The wafer design refers to the valve's compact, thin profile, which makes it easy to install between two flanges without requiring additional support.

The silent aspect of these check valves comes from their design that minimizes the noise generated during fluid flow. Traditional check valves can produce noise due to the abrupt closing of the disc when fluid flow is reversed. Silent check valves, however, employ a smoother closing mechanism that significantly reduces water hammer and noise, making them ideal for applications where quiet operation is essential.

Key Features

1. Compact Design The wafer design allows for easy installation in tight spaces, making them suitable for a variety of applications without the need for significant structural adjustments. 2. Unidirectional Flow These valves are designed to allow flow in one direction only, providing reliable backflow prevention.

4. Material Versatility Wafer type silent check valves can be constructed from a variety of materials, including stainless steel, cast iron, and PVC, making them suitable for different fluid types and environmental conditions.

Applications

wafer type silent check valve

Wafer type silent check valves have a wide range of applications across various industries, including

- Water Treatment Plants They are used to prevent backflow in pipelines, ensuring the integrity of the water supply. - HVAC Systems In heating and cooling systems, these valves help maintain fluid flow direction and protect equipment from damage caused by reverse flow. - Pumping Stations They are essential in systems where pumps are used to control fluid movement, preventing potential reversals that could lead to equipment failure. - Industrial Processes Various manufacturing and processing facilities utilize these valves for fluid management, ensuring smooth operations without the risk of backflow.

Advantages

The popularity of wafer type silent check valves can be attributed to several advantages

- Space-Efficient Their slim profile reduces the overall footprint of piping systems, conserving space. - Cost-Effective The simple design often leads to lower manufacturing costs and maintenance requirements, making them a cost-effective solution for many applications. - Ease of Installation These valves can be easily integrated into existing systems without extensive modifications, reducing installation time and labor costs. - Reduced Maintenance With fewer moving parts and a robust design, silent check valves often require less frequent maintenance compared to traditional check valves.

Considerations

While wafer type silent check valves offer numerous benefits, there are some considerations to keep in mind

- Flow Conditions It’s essential to evaluate the specific flow conditions in the application, as these valves may have limitations in certain high-velocity scenarios. - Pressure Ratings Ensure that the selected valve meets the pressure requirements of the system to prevent failure. - Installation Requirements Proper installation is crucial to ensure the functionality of the valve and avoid any potential issues with backflow.

Conclusion

Wafer type silent check valves represent a vital component in fluid management systems across diverse industries. Their innovative design offers a combination of efficiency, cost-effectiveness, and reliability. Understanding their features, applications, and limitations is key to leveraging their capabilities effectively. As industries continue to evolve and innovate, the role of these valves will remain crucial in ensuring smooth and silent fluid control.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025