Desemba . 16, 2024 05:17 Back to list

wafer style butterfly valve

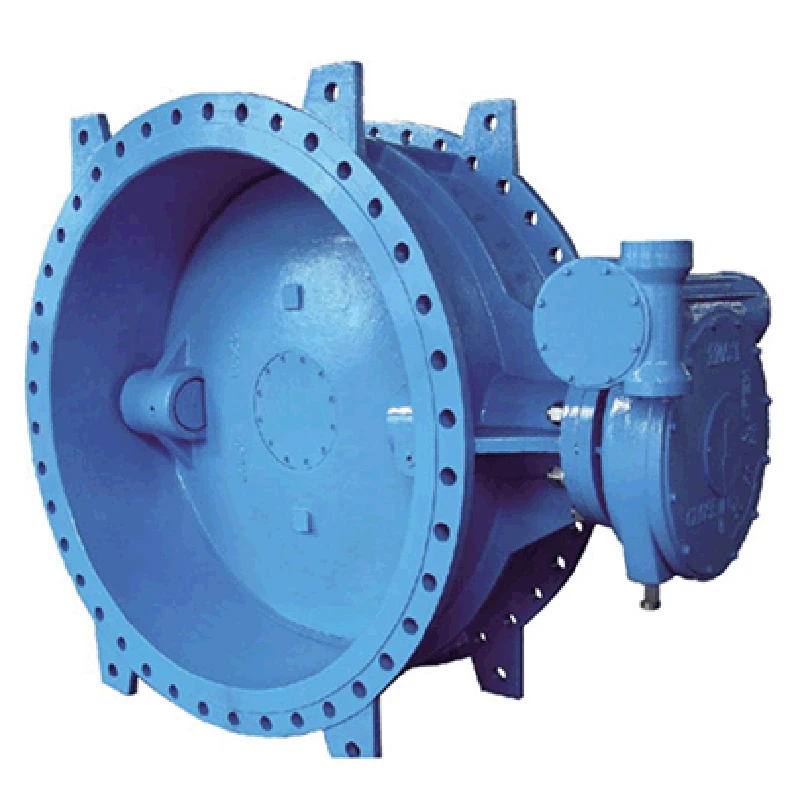

Understanding Wafer Style Butterfly Valves Features and Applications

Wafer style butterfly valves are a popular choice in various industries due to their compact design, ease of installation, and efficient performance. These valves offer a unique solution for flow control, making them essential components in systems ranging from water treatment plants to chemical processing facilities.

What is a Wafer Style Butterfly Valve?

A wafer style butterfly valve consists of a disc that rotates around a central axis to control the flow of fluid through a pipeline. Unlike traditional valve types, the wafer design allows for installation between two flanges without the need for additional fittings. This makes them particularly advantageous in space-constrained environments. The valve body typically consists of resilient materials such as cast iron, stainless steel, or PVC, providing durability and resistance to corrosion.

Key Features of Wafer Style Butterfly Valves

1. Space Efficiency One of the primary benefits of wafer style butterfly valves is their compact size. They are particularly useful in applications where space is limited, as their installation is seamless between two pipe flanges.

2. Lightweight Construction Compared to other valve types, wafer butterfly valves are lightweight, making transportation and installation more manageable. Their lower weight reduces the strain on piping systems and helps minimize installation costs.

3. Quick Operation The design of a butterfly valve allows for rapid opening and closing. This quick operation is crucial in applications requiring fast flow control or emergency shut-off capabilities.

4. Minimal Pressure Drop When fully open, the disc of a butterfly valve is positioned parallel to the flow direction, resulting in minimal obstruction. This feature helps in reducing the pressure drop across the valve and ensures efficient flow characteristics.

5. Versatility Wafer style butterfly valves can be used in various applications, from water and wastewater management to food processing and chemical industries. The ability to handle different media, including gases and solids, adds to their versatility.

wafer style butterfly valve

Applications of Wafer Style Butterfly Valves

Wafer style butterfly valves are extensively utilized in several industries due to their reliable performance and adaptability. Here are some typical applications

1. Water Supply and Distribution In municipal water supply systems, these valves are used for controlling water flow and regulating pressures efficiently. Their lightweight nature facilitates easier installation in complex systems.

2. Wastewater Treatment In wastewater treatment facilities, wafer butterfly valves help manage the flow of sewage and effluents. Their robust design allows them to handle aggressive media without deteriorating.

3. Chemical Processing The chemical industry often uses wafer style butterfly valves for their ability to handle corrosive substances. These valves can be specially designed with exotic materials to ensure longevity even in harsh environments.

4. Power Generation In power plants, these valves are essential for controlling cooling water systems, steam lines, and other critical processes. Their quick operation is vital for safety during operational contingencies.

5. Food and Beverage Industry Wafer style butterfly valves are also used in the food and beverage sector for sanitary applications. They can be easily cleaned and sanitized, ensuring compliance with health and safety regulations.

Conclusion

Wafer style butterfly valves are a reliable and efficient choice for fluid control across various industries. Their space-saving design, durability, and versatility make them ideal for numerous applications. As technology advances, the design and materials used in these valves continue to evolve, ensuring that they meet the increasing demands of modern engineering challenges. Whether you are involved in municipal water handling, chemical processing, or any other field, understanding the benefits and functionalities of wafer style butterfly valves will help you make informed decisions for your projects.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025